TUBING TESTER VALVE (TTV) from KINGWELL

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500 set/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Certification: | API, ISO |

| Brand: | KINGWELL |

| Type: | APR drill stem testing tools |

| Pressure: | high pressure |

| Service: | H2S + CO2 |

| Application: | oil well testing |

| Product mode: | Halliburton type, all could change with Halliburton parts. |

| Condition: | New |

| Standard: | NACE MR0175 |

| Maximum Pressure Rating: | 15000psi |

| Production Capacity: | 500 set/month |

| Packing: | seaworthy packing |

| Delivery Date: | 30days after the down payment received |

Product Description

Drill Stem Testing Tools Tubing Tester Valve

Description

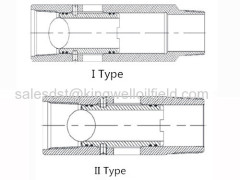

The Tubing Tester Valve (TTV) is a single shot annular pressure controlled flapper valve designed to be used during cased hole testing and perforating operations for pressure testing a workstring while running in the hole

Operation

The Tubing Tester Valve is always assembled with the flapper valve in the active position. This allows a small differential from the fluid below the valve to open the flapper to fill the string, and applied pressure from above the valve seals the flapper for tubing pressure tests. The tubing string can be pressured up against the flapper as many times as required.

When the tool is required to be disabled, pressure is applied to the annulus until the selected rupture disk bursts, allowing the mandrel to shift and causing the flap of the valve to be held in the open position. Once the rupture disk has been fired the tool remains fully open.

Specifications

Connection up | 3-1/2 API IF BOX (Premium Threads Available) |

Connection down | 3-1/2 API IF PIN (Premium Threads Available) |

Maximum Pressure Rating | 15,000psi |

O.D. | 5.00" |

I.D. | 2.25" |

Length | 56.45" |

Tensile Strength | 300,000 lbs |

Temperature | -22°F to 350°F |

Service | H2S + CO2 |

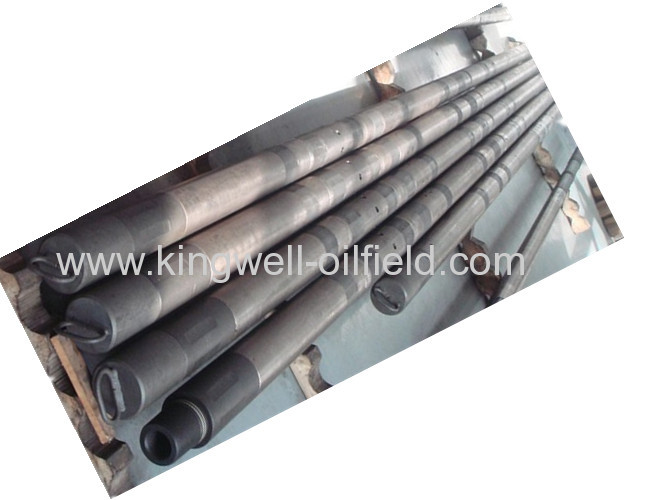

Pictures

About Us

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a professional supplier for oilfield products according to the API standard.

Our products have exported to USA, Canada, Egypt, India and UEA, etc with 40 FCL containers per month. Now, with high quality and short supply and good service, our products have got good reputation home and abroad .

Here we got some prise as follows.

Certifications

Kingwell is a CNPC & SINOPEC & BV certified company, having all the Quality Systems in place for design, planning, manufacturing and quality monitoring & traceability to ensure our products match the highest quality standards.

We test our products strictly according to the NACE MR 0175-2002 Standard and our quality assurance period is 12 months.

Certificates endorsed by DNV/BV/ABS and Documents we can supply with the shipments:

1. Pressure Test Certificate with Graph and time recorded.

2. Function Test

3. Rubber Products NACE Compliance

4. Material Mill Certificate and treatment characteristics

5. H2S Compliance

6. Service Manual

7. Parts Manual

8. Testing Procedures.

9. Open up type tool drawing for dressing purpose– if any.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum University and built up long term cooperation with China Aerospace Group for more than 10 years. Design Department is familiar with CAD and Pro-E facilities and has on rolls qualified & experienced engineers. Now, they are engaged in development of new products as required in the market place. Kingwell' products are validated in-house in a Test Well, a Sub-surface Type Test Facility with simulated well conditions up to 15000 psi Differential pressure , 400°F and Max 450°F.

Inspection and Test Facilities

We own the world-class facilities with professional laboratory technicians. The main facilities are Surface Testing (Hydraulic Testing Unit), high temperature heat treatment furnaces, API Gages (Master & Working), Profile Projector, tensile testing machine, pressure sensor and data acquisition system, Universal Testing Machine, Hardness Tester, Nitrogen Pump, Function Test Pump, Ultrasonic Thickness Tester etc. All the goods must be tested by several processes and must be qualified when packed.

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China

Minimum order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

Service

Kindly let me know if you have any interest or enquiry about our products. You are also always welcomed to come to our factory for a visit at your convenient time.

We will offer you a good price and show you our best service.