API standard oilfield Casing Elevator

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | DD/TA |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standards: | API 8A/8c |

| Machine Type: | Drilling Equipment |

| Use: | Well Drilling |

| Rated Load: | 35~150tons |

| Size: | 2 7/8-11 1/4" |

| Production Capacity: | 50 sets per month |

| Packing: | Standard export package |

| Delivery Date: | 20 days |

Product Description

API Spec 8A/8C Specification for Drilling and Production Hoisting Equipment

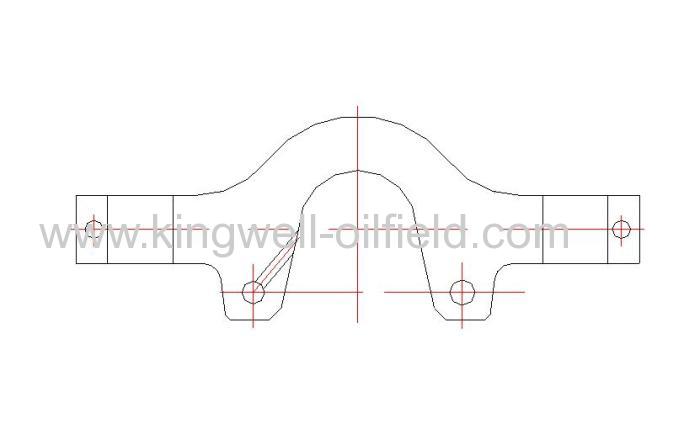

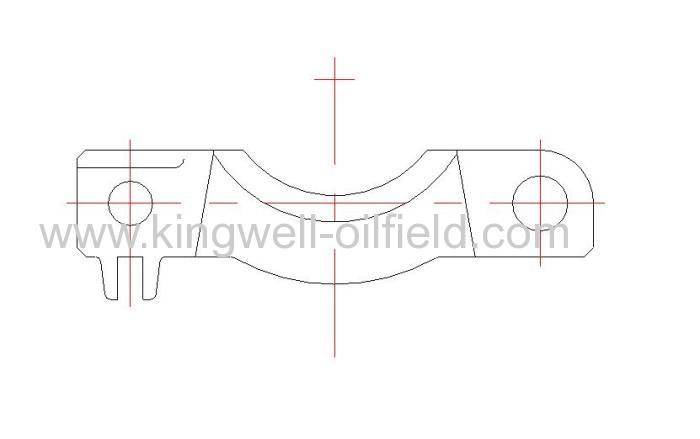

Model TA center latch elevators with square shoulder are suitable for handling drill pipes, drill collars, casing and tubings. The products shall be designed and manufactured according to API 8A/8CSpecification for drilling and production hoisting equipment.

| Pipe | Drill pipe | Casing | Tubing | ||||||||||

| Model | DD 65 | DD 100 | DD 125 | DD 150 | DD 250 | DD 350 | DD 100 | DD 150 | DD 65 | DD 100 | DD 125 | DD 150 | |

| Pipe OD(in) | 1.9 | ||||||||||||

| 2 3/8 | 2 3/8 | 2 3/8 | 2 3/8 | 2 3/8 | 2 3/8 | 2 3/8 | 2 3/8 | ||||||

| 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | 2 7/8 | ||||||

| 3 1/2 | 31 /2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | |||||||

| 4 | 4 | 4 | 4 | 4 | 4 | ||||||||

| 4 1/2 | 4 1/2 | 4 1/2 | 4 1/2 | 4 1/2 | 4 1/2 10 3/4 | 4 1/2 | 4 1/2 | ||||||

| 5 | 5 | 5 | 5 | 5 | 5 | 5 | |||||||

| 5 1/2 | 5 1/2 | 5 1/2 | 5 1/2 | ||||||||||

| Max Load | kn | 585 | 900 | 1100 | 1350 | 2250 | 3150 | 900 | 1350 | 585 | 900 | 1100 | 1350 |

| Ton | 65 | 100 | 125 | 150 | 250 | 350 | 100 | 150 | 65 | 100 | 125 | 150 | |

Forged steel parts of Ultrasonic Inspection Report

QR/SF17-12 №:1408059

Inspection Dept. | Technical & Quality Section | Process Card No. | UT-4-703 | Appointing Dept. | Metalwork shop |

Work-piece Description | Casing Elevator Body TA5″-100 | Production order No. | SF140726 | Product No. | 4143084 |

Process | After normalizingt | Heat No. | 4-140711-6 | Material | 35CrMoA |

Instrument Model | PXUT-350+ | Couplant | Machine oil | Inspection face | Ra≤12.5μm |

Probe | Normal probe2.5P,D20 | Reference reflecting body | large flat bottom | (mm) reference wave | 75% |

Probe faces | Top and bottom faces | Detecting proportion % | 100% | Reception standard | ASM E A388 |

Test Location and Defects Record:

| |||||

Defects are marked on the drawing. | |||||

Final Test Report for Casing Elevator

Test Pipe Size: 5″

Serial No.: 4143084 №:1408076

Test Items | Technical Requirements | Test Method | Test Results | Conclusions | |||

1 | Handling test |

Elevator should be open and close smoothly, and no blockage. Locking function is safe and reliable. |

Choose one size pipe within the applicable range. | √ | Pass | ||

2 | 1.5 times the rated load test | Elevator can clamp pipe tightly. Apply 1.5 times the rated load and remain at least for 5 minutes. After load test, check the elevator for functions. All functions should be ok, and no parts are deformed or damaged. | Choose one size pipe within the applicable range. | √ | Pass | ||

Pipe OD. | Rated load | Test load | |||||

5″ | 100 t | 150 t | |||||

3 | Painting , Package | Painting should be rust-proof and flat. All machined surfaces should be coated with grease. | Visual inspect | √ | Pass | ||

Product should clearly be mark the searial No., production No. and applicable size range. | √ | Pass | |||||

Documents supplied:Quality Certificate, Packing List, and Operation Manual. | √ | Pass | |||||

The elevator should be packed sturdily. | √ | Pass | |||||