Drill Stem Testing (DST) Tools Super Safety Valve

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | KW-DST-Super Safety Valve-064 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type:: | full bore drill stem testing |

| service:: | H2S, CO2 |

| Working pressure:: | 10000psi ~ 15000psi |

| standard:: | NACE MR0175 |

| ramlock:: | 5.0" OD x 18.0" LONG |

| valve ID: | 3.0" |

| valve bodyOD: | 8.0" |

| handing subOD: | 8.16" |

| Working pressure rating: | 15,000 PSI |

| operating temparature range: | 0 to 350oF. (-18oC to 177oC) |

| Production Capacity: | 100 sets per month |

| Packing: | wood case or steel carton |

| Delivery Date: | within 1-2 month(s) after receiving prepayment |

Product Description

Drill Stem Testing Tools Super Safety Valve

Standard: API

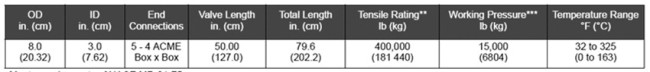

Overall length w/handing sub: 142.65"

Valve section length: 50.90"

Ram lock: 5.0" OD x 18.0" LONG

Valve body OD: 8.0"

Handing subOD: 8.16"

Condition:New

Briefly Introduce

The Super Safety valve (SSV) is a master valve used for testing operations from jack-up or land rigs. The SSV is installed in the test string so that a BOP ram can be closed on the ram lock sub located in the top section of the valve. The annulus is then protected by the BOP rams, and the test string is protected by the safety valve. The Super Safety valve is capable of cutting wireline and 1.5-in. coiled tubing. If equipped with a cutter ball, it is capable of cutting 2-in. OD, .125-in. wall coiled tubing using a nitrogen dome charge or by applying balance line pressure

Features and Benefits

The Super Safety valve is controlled by two hydraulic lines and contains a chemical injection port for injecting chemicals at the valve body further downhole to an injection sub or to actuate a subsurface safety valve. The valve is held open by maintaining hydraulic pressure on the control line. The valve is designed to close by spring force but incorporates a nitrogen dome charge chamber to provide increased closing force and to lessen the time required for closing. This feature gives the valve the ability to cut wireline and coiled tubing without adding balance line pressure.

• Normally closed/fail-safe

• Maintains pump-through capabilities at all times

• Nitrogen dome charge for fast response

• Capable of cutting 1.5-in. coiled tubing, or if equipped with a cutter ball 2-in. OD, .125 in. wall thickness coiled tubing

• Small 8-in. OD fits inside 9 5/8-in casing

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

Below are specfor you reference:

Company introduction

Xi'an KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL) is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, DST tools and Solid control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices. Our products have been exported to Europe, American and Middle East.

Here we got some prise as follows.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

Inspection and Test Facilities

We own the world-class facilities with professional laboratory technicians. The main facilities are Surface Testing (Hydraulic Testing Unit), high temperature heat treatment furnaces, API Gages (Master & Working), Profile Projector, tensile testing machine, pressure sensor and data acquisition system, Universal Testing Machine, Hardness Tester, Nitrogen Pump, Function Test Pump, Ultrasonic Thickness Tester etc. All the goods must be tested by several processes and must be qualified when packed.

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who purchase our products.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China

Minimum order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

Any enquiry of above products or relative parts, PLS feel free contact back, and we will offer you a good price and show you our best service.