HYDRAULIC AND MECHANICAL DRILLING JAR

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 1000 set per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | API KINGWELL DRILLING JAR 002 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| standard: | API 7-1 |

| type: | 5-7/8"-8" Drill Jar for well drilling |

| Brand: | KW |

| Export: | Worldwide |

| Usage: | Downhole stuck freeing tool |

| Delivery Time: | Fast |

| Supply ability: | 1000 per month |

| Production Capacity: | 1000 set per month |

| Packing: | EXPORT PACKAGES |

| Delivery Date: | 20 days after received advance payment |

Product Description

HYDRAULIC AND MECHANICAL DRILLING JAR

1 Drilling Jar is a downhole tool

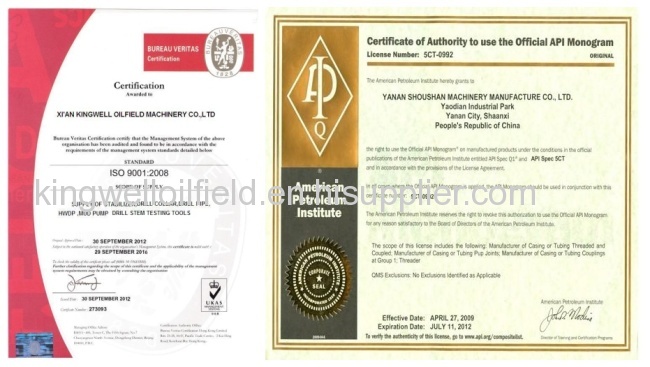

2.API 7-1 certificate

3.with high quality and short supply

4.Model "JYQ" Hydro-mechanical Drilling Jar

GENERAL

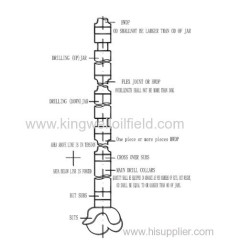

Model "JYQ" Hydro-mechanical Drilling Jar is a double-action drilling tool used to free the stuck tools and make a jarring. It integrates the up jar and down jar and can deal with the stuck accident happened in shortest time during the drilling. It is an ideal jarring tool for the directional well and deep well.

Operators can make an adjustment for lifting and lowering drill tool (without the adjustment of torque and outside) to get the releasing up jar or down jar force when used the Drilling Jar downhole. Moreover, the operator can adjust the jarring force from small to maximal force required. It can be broadly used for drilling, coring, fishing and workover because of its easy operation, convenience and high reliability

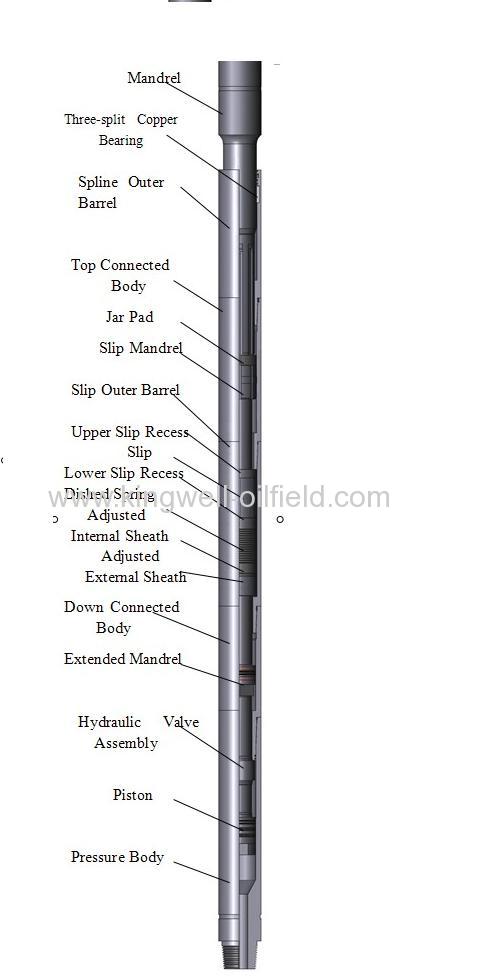

Product detail:

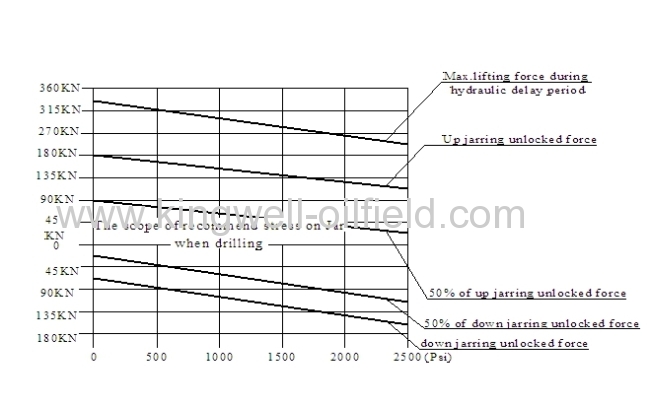

Repeat above-stated procedures as to produce a continuous up jarring motion. Maximum up jarring releasing load is different under various hydraulic pressure drop of bit (See Table 5-1). So, maximum up jarring releasing load can be decided by hydraulic pressure drop on bit.

5. SPECIFICATIONS

The specifications can see Table 5-1.

Table5-1 The specification of Model "JYQ" Hydraulic Drilling Jar (Metric Unit)

Model | O.D mm | I.D mm | Connection API | Up Jarring Stroke mm mm | Down Jarring Stroke mm | Working Torque KN.m | Max. Tensile Load KN | Max. up Jarring KN | Max. down Jarring KN | All Length mm | Piston areas mm2 |

JYQ121 | 124 | 50.8 | NC38 | 227 | 102 | 125 | 1300 | 250 | 200 | 4500 | 2516 |

JYQ121Ⅱ | 121 | 57.2 | NC38 | 227 | 102 | 125 | 1300 | 250 | 200 | 4500 | 2827 |

JYQ159 | 159 | 57 | NC46 | 230 | 152 | 150 | 2220 | 580 | 360 | 5007 | 6446 |

JYQ165 | 165 | 70 | NC50 | 230 | 152 | 150 | 2220 | 580 | 360 | 5007 | 6446 |

JYQ178 | 178 | 70 | NC50 | 230 | 152 | 150 | 2220 | 580 | 360 | 5007 | 6446 |

JYQ197 | 197 | 76.2 | 65/8REG | 232 | 152 | 195 | 2525 | 800 | 400 | 5095 | 9538 |

JYQ203 | 203 | 76.2 | 65/8REG | 232 | 152 | 195 | 2525 | 800 | 400 | 5095 | 9170 |

JYQ241 | 241 | 76 | 75/8REG | 230 | 152 | 130 | 5400 | 1400 | 400 | 5300 | 17192 |

(Imperial Unit) | |||||||||||

Model | O.D in | I.D in | Connection API | Up Jarring Stroke mm mm | Down Jarring Stroke mm | Working Torque KN.m | Max. Tensile Load KN | Max. up Jarring KN | Max. down Jarring KN | All Length in | Piston areas in2 |

JYQ121 | 4 7/8 | 2 | NC38 | 8 7/8 | 4 1/8 | 92000 | 300000 | 56000 | 45000 | 177 1/8 | 3 7/8 |

JYQ121Ⅱ | 4 3/4 | 2 1/4 | NC38 | 8 7/8 | 4 1/8 | 92000 | 300000 | 56000 | 45000 | 177 1/8 | 4 3/8 |

JYQ159 | 6 1/4 | 2 1/4 | NC46 | 9 1/4 | 5 7/8 | 110000 | 500000 | 130000 | 80000 | 197 1/8 | 9 7/8 |

JYQ165 | 6 1/2 | 2 3/4 | NC50 | 9 1/4 | 5 7/8 | 110000 | 500000 | 130000 | 80000 | 197 1/8 | 9 7/8 |

JYQ178 | 7 | 2 3/4 | NC50 | 9 1/4 | 5 7/8 | 110000 | 500000 | 130000 | 80000 | 197 1/8 | 9 7/8 |

JYQ197 | 7 3/4 | 3 | 65/8REG | 9 1/8 | 5 7/8 | 140000 | 560000 | 180000 | 90000 | 200 1/2 | 36 |

JYQ203 | 7 7/8 | 3 | 65/8REG | 9 1/8 | 5 7/8 | 144000 | 560000 | 180000 | 90000 | 200 1/2 | 14 1/8 |

JYQ241 | 9 1/2 | 3 | 75/8REG | 9 1/2 | 6 | 95883 | 1200000 | 314732 | 90000 | 208 1/2 | 60 1/2 |

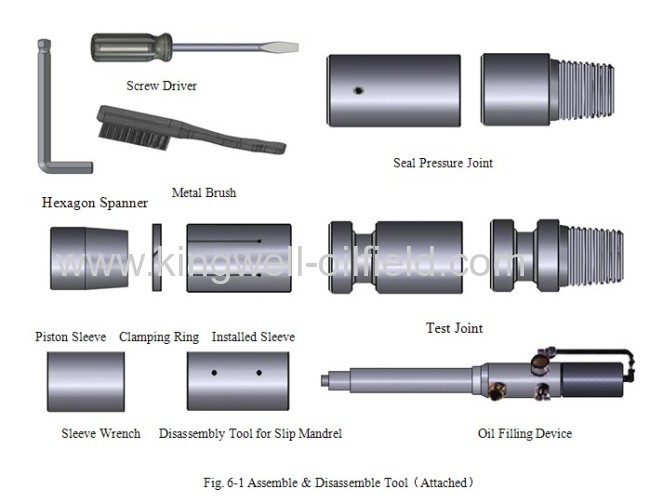

Assemble & Disassemble Tool(Attached)

About us:

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce stabilizer, forgings, BOP & spare parts and DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

11.ORDER STATE

1) If you need to order steel products, you can only provide its name, quantity and the specification of Jar. Please replace all the rubber seal system once time.

2) Please specify the specifications of special products.

The aging period of rubber seal system is 18 months