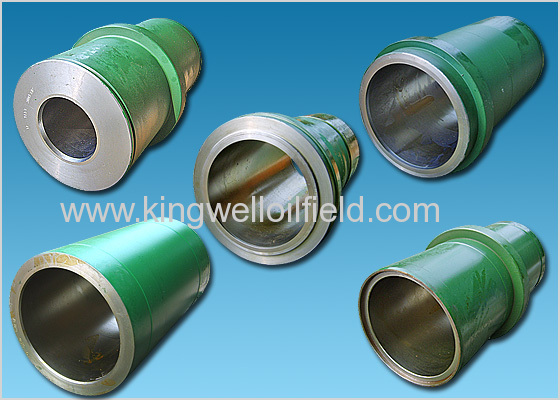

Mud Pump Ceramics Cylinder Liner

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50000 pcs/Year |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | F-1300 Mud Pump |

|---|---|

| Means of Transport: | EXPRESS, Ocean, Air, Land |

| Type: | Others |

| Certification: | Others |

| Brand Name: | KINGWELL |

| Origin: | China |

| Model: | F-500,F-800, F-1000,F-1300,F-1600,F-2200 |

| Material: | Forged steel |

| Theory: | Reciprocating Pump |

| Structure: | Piston Pump |

| Usage: | Oilfield |

| Fuel: | Diesel |

| Power: | Hydraulic |

| Application: | Well drilling |

| Pressure: | High pressure |

| Production Capacity: | 50000 pcs/Year |

| Packing: | Polywood case or steel carton |

| Delivery Date: | 25days after the deposit received |

Product Description

1. Triplex mud pump liner(Ceramics Cylinder Sleeve ):

product introduce and advantage

Our ceramic liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. We provide Zirconia(ZrO3) Sleeves as wellas Alumina(Al2 O3.) sleeves., of which Zirconia exhibits better impact strength, higher hardness and be honed to finer surface finishes thanalumina.

Ceramic liners are currently thepremium liner offered today. Ceramic liners have been known to operate well overthe 7000-hour work. Due to the high hardness of the ceramic surface, they wearsubstantially less than other liner types. This translates into longer pistonoperating times. If the correct conditions are present, the cost per operatinghour can be much less than that of the other liner types

Size in inches: 4,4-1/2,5 5-1/2, 6,6-1/4, 6-1/2,6-3/4,7

Size in mm: 100,110,120,130,140,150,160,170,180

2. Introduction of Bi-metal Liner:

Heat Treated Bi-metal Liner for Mud Pump

Outer surface: premium carbon steel

Inner sleeve: high chrome

Hardness: HRC60~67

3. API Std. Mud Pump Liner for Oil Drilling:

A cylinder liner ( or cylinder sleeve) is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine. Our products after quenching technology for the surface and heat treating, the forged liner is with high intensity, strong tenacity and wearability. Main functions as belows:

(1) Formation of sliding surface:

The cylinder liner, serving as the inner wall of a cylinder, forms a sliding surface for the piston rings while retaining the lubricant within. The most important function of cylinder liners is the excellent characteristic as sliding surface and these four necessary points.1) Less wear on the cylinder liner itself2) Less wear on the partner piston ring 3) Less consumption of lubricant

(2) Heat transfer:

The cylinder liner receives combustion heat through the piston and piston rings and transmits the heat to the coolant.

(3) High temperature and high pressure:

A cylinder wall in an engine is under high temperature and high pressure, with the piston and piston rings sliding at high speeds. In particular, since longer service life is required of engines, forging cylinder that have excellent wear-resistant properties are only used for cylinder parts.

We can provide the following liners: GARDNER DENVER: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11;

IDECO: T–500, T–800, T–1000, T–1300, T–1600

4. Goods Kingwell be able to supply: