API 7-1 16" spiral blade stabilizer for oilfield

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 500 per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | API 7-1 16" stabilizer |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standard: | API |

| Processing type: | Forging |

| Machine type: | drilling tool |

| Packaging & Delivery Packaging Detail: | wooden box or as your requirement |

| Use: | Well Drilling |

| Hard-facing: | HF1000, HF2000, HF3000, HF4000, HF5000 |

| Delivery Detail: | 20 days after the payment received |

| Size: | 8-3/8" |

| Brand: | KW |

| Supply Ability: | 5000pcs per mont h |

| Production Capacity: | 500 per month |

| Packing: | EXPORT PACKAGES |

| Delivery Date: | 30 days after received advance payment |

Product Description

API 7-1 16"spiral blade stabilizer for oilfield

1.Quick details:

1. Material: AISI 4145H Mod Alloy steel, Non magnetic steel, etc.

2. Types: Drill String type and Near bit type.

3. Use: It is mainly used to stabilize the drilling tools in the process of drilling hole.

4. Standard: API Spec 7-1 and ISO Standard.

5. Inspection&Test: When producing, traceability are maintained from the receipt of raw material to completion of final products, and serial numbers are die-stamped on each work piece body. During each manufacturing process, inspection and test are performed.

2. Usage:

| Stabilizer is one useful tool for drilling operation. Kingwell offers a wide variety of near bit stabilizers and string stabilizers according to API SPEC 7. All drilling stabilizers are integral style, also can be highly customized as per customer's requirements. Spiral blade stabilizer is integrally made of high strength alloy steel AISI 4145H, usually with 3 blades or 4 blades. The working surface of spiral stabilizer is provided with carbide insert, diamond compound insert, or overlay welding etc. |

3. Attractive Point:

A. Complete range of Stabilizer according API 7-1 Spec

B. The Hanrdfacing is HF1000~HF5000.

C. Roller type:

Type T: Milled, machined with hard faced sharp teeth, for soft formations.

Type F: Milled, machined with hard faced flat teeth, for medium hard formations.

Type B: Equipped with pressed-in tungsten carbide buttons, for hard formations.

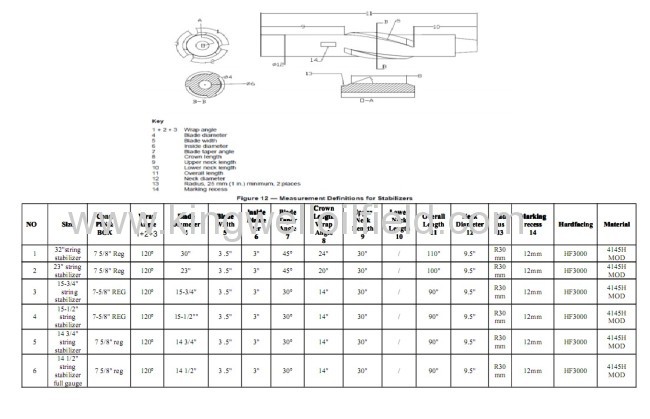

4. Technical specifications of spiral blade stabilizer

Bit Size | Working O.D. | End O.D. of Body | I.D. | Length | Thread Code on Both Ends | |||

String Type | Near Bit Type | |||||||

Top | Down | Top | Down | |||||

6 | 152.4 | 121 | 51 | 1,200 | NC38 | 3-1/2 REG | ||

6-1/4 | 158.7 | |||||||

6-1/2 | 165.1 | |||||||

7-1/2 | 190.5 | 159 | 57 | 1,600 | NC46 | 4-1/2 REG | ||

7-7/8 | 200 | |||||||

8-3/8 | 212.7 | 159 | 71 | 1,600 | NC46 | |||

8-1/2 | 215.2 | 159 | ||||||

8-3/4 | 222.2 | |||||||

9-1/2 | 241.3 | 178 | 1,600 | NC50 | NC50 | NC50 | 6-5/8 REG | |

9-5/8 | 244.5 | 1,800 | ||||||

9-7/8 | 250.8 | |||||||

12-1/4 | 311.2 | 203 | 76 | 1,800 | NC56 | NC56 | NC56 | 6-5/8 REG |

16 | 406 | 229 | 2,000 | NC61 | NC61 | NC61 | NC61 | |

5. Workshop & Production Line:

6. Inspection & Quality Control:

Our STABILIERS cover all API Standard scope from 6"-36" with strickly inspection, which all the goods should be checked one by one before packing. Euipped withthe world-class facilities and professional laboratory technicians, we pay more attention the quality of every products.

7. Drawing:

8. Delivery time:

10 days in stock, 30 days after received prepayment.

9. Paperwork:

A. Commerial Invoice

B.Packing List

C. Bill of Lading

D. Inspestion Report and Mill Test Certificate

E. C/O

F. Production Record

10. Recent products products:

11. Warrenty:

one year after shipment or inspected by clients.

Please feel free to contact me if any prodcts intewrest you!