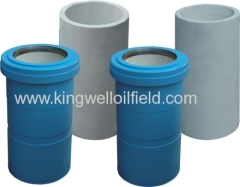

API Standard Mud Pump Zirconia Ceramic Liner

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 10000pcs/Year |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | F-1300 Mud Pump |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Vacuum Pumps |

| Certification: | Others |

| Brand Name: | KINGWELL |

| Origin: | China |

| Model: | F-500,F-800, F-1000,F-1300,F-1600,F-2200 |

| Theory: | Reciprocating Pump |

| Material: | Zirconia ceramic with steel |

| Standard: | API & ISO |

| Application: | Oil well drilling |

| Outer surface: | 45#round steel |

| Inner sleeve: | zirconia ceramic |

| Process: | forging or casting |

| Fuel: | Diesel |

| Production Capacity: | 10000pcs/Year |

| Packing: | Polywood case or steel carton |

| Delivery Date: | 25days after the deposit received |

Product Description

1. Specifications:

1). size: 3.25", 5",5.5",6",6.5",7",8",9"

2). Highhardness and wear resistance

3).Longer service life than ZTA and Alumina ceramic piston

4). Customization acceptable

5). Small MOQ

6). Quick delivery

7) Used in oil well, chemical industry

2. Advantanges:

Mud pump liner made of Zirconia ceramic can offerlifetime cost savings, longer service, better performance and safer operationthan sleeves made of more commonly used chrome iron or alumina ceramic,according to data developed by oilfield servicer.

3. API-7K mud pump zirconia ceramic liner for oil drilling:

We supply both zirconia ceramic and bimetal liner for Emsco, Gardner Denver, National, Oil well, Continental, Ideco, and China 3NB mud pump and supply other mud pump parts.

4. Applications:

The ceramic liner is used as a kind of mud pump fluid end parts in the oil drilling industry.

5. Features:

Compared with the metal liner, the ceramic liner is wear and corrosion resistant and has extended working life. The ceramic liner helps reduce drilling cost and labor intensity. Made of internationally advanced, new material toughened zirconium oxide, the liner provides fracture toughness of K10-15Mpa (10 times that of the traditional one), and bending strength of σ600-800Mpa. The ceramic liner has excellent wear and corrosion resisting properties, with the Weber number being m18 and the elastic modulus of E200Gpa.

6. Parameters:

EMSCO | F-1000 | F-1300 | FA-1300 | F1600 | FA-1600 | FB-1300 | FB-1600 |

F-350 | F-500 | F-650 | F-800 | DB-550 | D-300 | D-375 | |

D-700 | |||||||

IDECO | T-500 | T-800 | T-1000 | T-1300 | T-1600 | ||

GARNDER-DENVER | PZ-7 | PZ-8 | PZ-9 | PZ-10 | PZ-11 | PZ-L | PA-8 |

PAH | FY-FXD | FO-FXO | FD-FXX | FG-GXG | |||

NATIONALOILWELL | 10-P-130 | 12-P-160 | 8-P-80 | 7-P-50 | K-700 | K-700A | K-500 |

K-500A | K-380 | A1700-PT | A1400-PT | A1100-PT | 220P | 218P | |

A850-PT | A350-PT | JWS | |||||

CHINA | 3NB-350 | 3NB-500 | 3NB-800 | 3NB-1000 | 3NB-1300 | 3NB-1600 | 3NB-2200 |

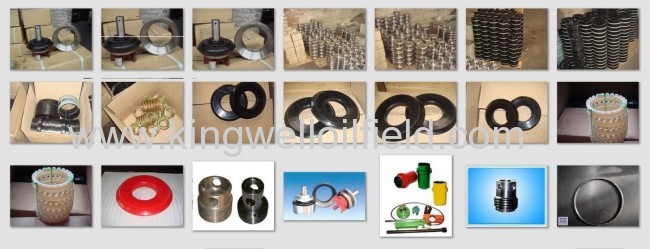

7. Products Kingwell able to supply:

8. Other mud pump spare parts kingwell be able to supply:

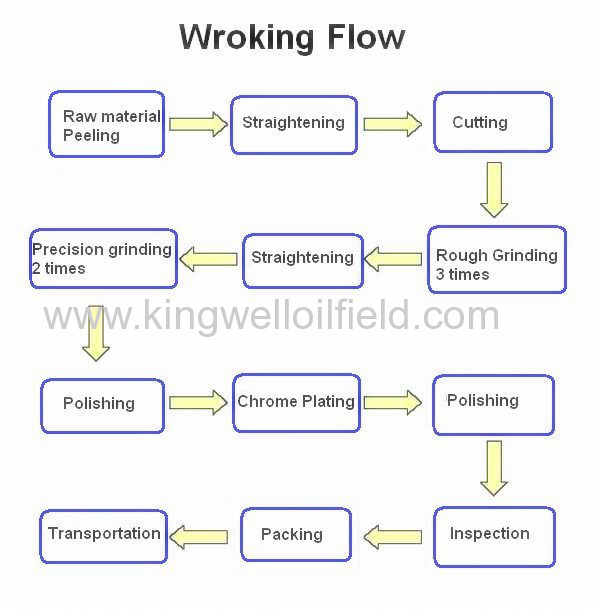

9. Kingwell working flow for the spare parts:

Any enquiry for above spare parts, kindly contact with us and we will reply you within 24 hours.