EMSCO API Mud Pump Hydraulic Cylinder

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 2000Pcs/Year |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | API Mud Pump F-800, F-1000, F-1300, F-1600, F-2200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Certification: | Others |

| Brand Name: | KINGWELL |

| Origin: | China Main Land |

| Structure: | Piston Cylinder |

| Power: | Hydraulic |

| Application: | Mud pump |

| Usage: | Oilwell Drilling |

| Certification: | ISO &API specification |

| Condition: | New and unused |

| Pressure: | High pressure |

| Size: | Customize |

| Production Capacity: | 2000Pcs/Year |

| Packing: | Polywood case or steel carton |

| Delivery Date: | 30days after the down payment received |

Product Description

1. Specifications:

1). forged alloy steel hydraulic cylinder

2). vertical structure

3). dimension in accordance with API standard

2. Features of Mud pump hydraulic cylinder:

1). Heat-treated and internally hardened for high durability; available in various materials to meet a wide range of applications; standard one-or and/or two-piece configuration, with designs available for pressure of 5000, 7500, and 10000psi(351,527,and703kg/cm2); discharge connections available on each side; suction connections oneach side or front center

2). Adapt most third party fluid-end modules to the mud pumps, eliminating the need for drilling contractors to stock fluidend parts from several manufacturers. Supply heat-treated,internally hardened forged alloy steel modules, if the drilling contractor doesn't specify third party fluid ends.

3). Made from the premium alloy steel AISI8620 or 4135, with thermal refining treatment, rigid inspection, as well as the strict Nonde structive Examination performed forensuring no internal flaw.

3. Photos of Hydraulic cylinder:

4. Other spare parts of Kingwell can supply:

5. Manufacturing facility:

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop:

6. Why you choose Kingwell as your pump supplier:

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price: We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

5). We can offer unitized pump package according to your different needs.

7. Kingwell inspection machine:

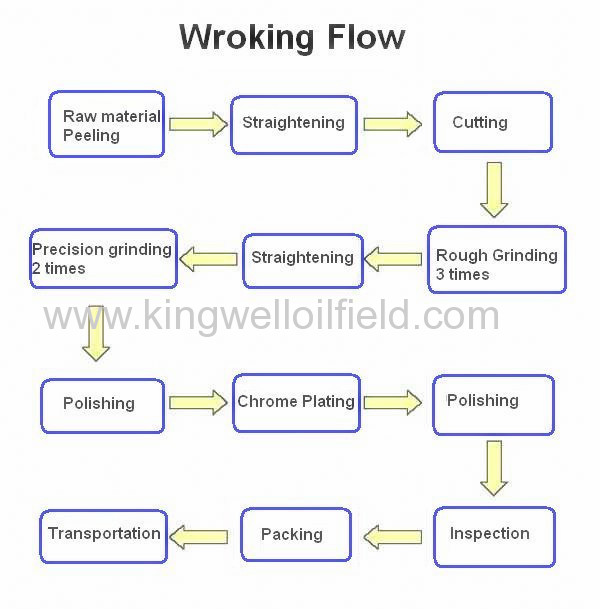

8. Kingwell Working flow:

9. Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who cooperated with us.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

10. Product delivery:

Payment term: 30% deposit by T/T or L/C and 70% before shipment.

Warranty: Warranty period is 12 months after installation.

Origin: China Mainland.

Minimum order: 1 sets

Packaging: wood case or steel frame which suitable for long term transportation.

Delivery Date: within 30days after receiving the deposit.

Logo: KW or customize.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

11. Shipment

Kingwell are experienced in production and also the shipment, our goods were sold to wordwide and has been accepted by the end users.

Any enquiry for above products or mud pump spare parts, kindly contact with us. A competitive price and good service will be shown you.