API KINGWELL 7-1 Near Bit & Drilling String Stabilizer 008

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 150 pcs per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | 6"~36"/42" |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Kingwelloilfield |

| Place of Origin: | Shaanxi China (Mainland) |

| Application: | Drilling industry |

| Material: | 4145H MOD, 4330V MOD, Non-mag material |

| Type: | Forged stabilizer |

| Dimension: | Various |

| Usage: | Oil Drilling |

| Colour: | as customer's requests |

| OD of bits: | 6"~36"(finished) 42"(forgings) |

| Standard: | API 7-1 |

| HF range: | HF1000~HF5000 |

| Production Capacity: | 150 pcs per month |

| Packing: | wood case or steel carton |

| Delivery Date: | according to actual quantity and size |

Product Description

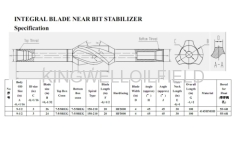

API 7-1 Near Bit & Drilling String Stabilizer

Specifications:

1. Standard: API 7-1

2. Type: String Type; Near Bit Type.

3. Steel Grade: AISI 4145 H; Non-Magnetic.

4. Size: Bit (6''---36'') * ID (1 3/4''---3 1/2'') * Length (40').

5. Cold Rolling of Thread Roots

6. Stress Relief Groove

7. Thread Surface Process: Phoscoating or Copperize Process Treatment.

8. Hard Facing Material: Carbide Insert; Diamond Compound Insert; Low Temperature Brazing Tungsten Carbide Slug; Surface Bead Welding Abrasive Welding Rod; etc.

9.Cast Steel Thread Protector.

10. Delivery Condition: Forged Bar; Semi-Finished; Finished Stabilizer.

Products range:

Bit Size (in) | Working OD (mm) | End OD of body(mm) | ID (mm) | Length (mm) | Thread code on both ends | |||

Drill string type | Near bit type | |||||||

Top | Down | Top | Down | |||||

6 | 152.2 | 121 | 51 | 1200 | NC38 | 3 1/2 REG | ||

6 1/4 | 158.7 | |||||||

6 1/2 | 165.1 | |||||||

7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG | ||

7 7/8 | 200 | |||||||

8 3/8 | 212.7 | 159 | 71 | 1600 | NC46 | |||

8 1/2 | 215.2 | 159 | ||||||

8 3/4 | 222.2 | |||||||

9 1/2 | 241.3 | 178 | 1600 | NC50 | NC50 | NC50 | ||

9 5/8 | 244.5 | 1800 | 6 5/8 REG | |||||

9 7/8 | 250.8 | |||||||

12 1/4 | 311.2 | 203 | 76 | 1800 | NC56 | NC56 | NC56 | 6 5/8 REG |

16 | 406 | 229 | 2000 | NC61 | NC61 | NC61 | NC61 | |

17 1/2 | 444.5 | |||||||

24 | 609.6 | |||||||

26 | 660.4 | |||||||

28 | 711.2 | |||||||

Note: Stabilizer can be madeaccording to customer's special requirement | ||||||||

Hardfacing for integral blade stabilizers we can supply:

HF1000/HF2000/HF3000/HF4000

Refered photos:

Stocked items:

Quality test:

Our factory:

Kingwell introduction:

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce stabilizer, forgings, BOP & spare parts and DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Welcome any of your enqiry!