Stainless Steel Forged Cylinder

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DAP,CIP,EXW, |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 1500 tons/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Model No.: | KINGWELL FORGED 013 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Kingwelloilfield |

| Place of Origin: | Shaanxi China (Mainland) |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS |

| Application: | Drilling equipment |

| Material: | Stainess steel |

| Type: | Alloy steel |

| Alloy or not: | Alloy |

| Colour: | Bright or black |

| Technique: | Forged |

| Delivery condition: | Forged, annealed, finishing |

| Diameter: | 90mm |

| Production Capacity: | 1500 tons/month |

| Packing: | seaworthy packing |

| Delivery Date: | according to actural quantity |

Product Description

Stainless Steel Forged Cylinder

Specifications:

1. Size range:Big size, or size as customer request

2. Materials: Alloy steel, carbon and stainless steel

3. Process: Rolled

4. OD:5000mm

5. OD 5000mm, Thickness 600mm

6. Rough machining, Finished machining

Dieforgingsteel cylinder

Specifications

OEM precision forging steel cylinder

forged steel cylinder Rough machining forging

WE DO THE BEST FOR FORGINGS.

OUR COMMITMENT: COMPETITIVE PRICE, HIGH QUALITY AND GOODSEVICE

General ring:

Specification:

2: Materials: carbon ,stainless and alloy steel

3: Measurement: within 16 meters

High quality flexible material forging steelring:

Specification:

1: Forging steel cylinder

2: Materials: carbon ,stainless and alloy steel

3: Measurement: Per customer's drawing

Detail description:

1: Name: General forging steelcylinder

2: Certificates: ISO9001-2008, SGS,PED

3: Products ability: 3000 ton/month

4: Surface: polishing or per customer's requirement

5: Proces: hot forging

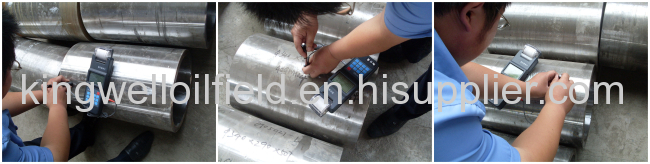

Quality Control:

1: On line inspection, we perform 100% on line inspection during productionnot to release any problem during production.

2: 100% inspection on each finished products.

3: Customer's own inspection.

4: Third party inspection.

5: UT( Ultrasonic Testing), MT, X-ray test, Spectrometer, Tensile strength,Impact test machine, Hardness tester

Packing:

Superiority 1. We had already passed the authentification by the ISO9001-2008, and established a completed set of quality assurance system. 2. Under such a complete set of quality assurance systems, there is acomplete set of regulations for ordering, order handling, quality design,purchasing raw materials, working out production plan, production, test andinspection, packaging, storage, delivering, etc. 3. We also have a complete set of equipment and techniques for testing andcontrolling the performance of the forging products, which ensures our productquality to take a leading position among the products in domestic market andreach the international standard. |

Any enquiry, pls contact us freely by email or telephone!