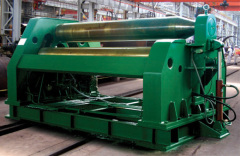

metal sheet roll forming machine

5000.0~80000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30 Set/Sets per Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nantong, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Press Brake Machine, Shearing Machine |

Product Detail

| Model No.: | W11-25X2000 |

|---|---|

| Means of Transport: | Ocean |

| Control:: | NC |

| ELECTRICAL EQUIPMENTS:: | SIEMENS |

| BLADE:: | 42CrMo |

| QUALITY CERTIFICATION:: | CE |

| Machine Type:: | Roller-Bending Machine |

| Raw Material:: | Sheet / Plate Rolling |

| WARRANTY:: | 100% one year |

| Production Capacity: | 30 Set/Sets per Month |

| Packing: | Covering with colour |

| Delivery Date: | Within 20-35 days... |

Product Description

metal sheet roll forming machine W11-25X2000

Simple description of machine:

High precision end pre-bending.The straight edge length can be set freely, the upper roller press to pre-bend.NC control, high productivity

Parameters are controlled by NC, easy for opeartion, improve the productivity greatly.

Precision of the superior productsUnique crooked craft , the high-accuracy tip is curved in advance, the crooked angle after not having in succession, the crooked course is digital control.Man-machine dialogue controls the high-efficient intelligence of interfaces to operatePeculiar crooked craft software, the interactive window, the automatic compensation of the crooked course, operate singly, high-efficient and safe and convenient!Abundant crooked formHave rolls of form to make O type, U type, many sections of R ,etc. different forms.Choice of many models According to the use or users' enquiry, count and show the model economily, TC numerical control model chooses.

1) The upper roller

upper rolls device composed of main cylinder, upper bearing pedestal, upper rolls, double self-aligning bearing .two cylinders provide the pressure for upper roll bending , main cylinder working pressure is 20 Mpa ,max pressure of upper roll multiply 0.8 times to compensate for pre-bending. Upper roll two ends fit with double self-aligning bearing to reduce the friction and motor power. The material of upper roll is 42CrMo , heat treatment is HB220-280. HRC 45-55

2) Down roll and level motion device.

The material of down roll is 42CrMo , heat treatment is HB220-280.. it composed of down of roll, down roll bearing pedestal, down roll input gear, down roll, glide bearing. Down bearing adopt SF-2 oil glide bearing.

Level motion motor supply the power, through the strap drive to CWU worm wheel and pole speed reducer. Upper roll level motion drove by worm wheel and pole to finish bending in dissymmetry form.

3) Support device

Composed of sloping block device, support device, support rolls bearing pedestal, support lifting device, support rolls can adjust up and down. The adjustment depend on plate speciation. The material of support is 45# , heat treatment is HB220-280, it made up in helix sharp to protect the surface.

Specification | Max roll Thickness (mm) | Max roll width (mm) | Yield strength (Mpa) | Roll speed (m/min) | Min roll dia (mm) | Upper roller dia (mm) | down rollers dia (mm) | bottom rollers distance (mm) | Motor (kw) | Dimension (mm) |

W11-4X1500 | 4 | 1500 | 245 | 5 | 300 | 150 | 140 | 185 | 3 | 2900x720x1000 |

W11-6X1500 | 6 | 1500 | 245 | 5 | 380 | 160 | 140 | 220 | 4 | 2900x720x1000 |

W11-6X3200 | 6 | 3200 | 245 | 4.5 | 380 | 220 | 180 | 280 | 7.5 | 4850x1100x1100 |

W11-8X2000 | 8 | 2000 | 245 | 4.5 | 400 | 185 | 170 | 260 | 5.5 | 3700x820x1050 |

W11-12X2000 | 12 | 2000 | 245 | 4.5 | 550 | 240 | 180 | 280 | 7.5 | 3650x1100x1100 |

W11-12X3000 | 12 | 3000 | 245 | 4 | 700 | 280 | 240 | 360 | 11 | 4900x1300x1300 |

W11-16X2000 | 16 | 2000 | 245 | 4 | 600 | 260 | 220 | 320 | 7.5 | 3700x920x1200 |

W11-16X3200 | 16 | 3200 | 245 | 4 | 850 | 340 | 260 | 430 | 15 | 5300x1400x1400 |

W11-20X2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 260 | 430 | 15 | 4600x1400x1400 |

W11-25X2500 | 25 | 2500 | 245 | 4 | 900 | 370 | 270 | 480 | 22 | 5600x1550x2000 |

W11-30X3200 | 30 | 3200 | 245 | 4 | 1200 | 480 | 400 | 600 | 37 | 7600×2300×2600 |

W11-40X2000 | 40 | 2000 | 245 | 4 | 1200 | 500 | 400 | 600 | 37 | 6400×2300×2800 |

W11-50X3000 | 50 | 3000 | 245 | 4 | 2000 | 600 | 480 | 700 | 60 | 9900×3100×3500 |

W11-60X3000 | 60 | 3000 | 245 | 4 | 2000 | 700 | 560 | 800 | 75 | 9700×3200×2700 |

Category: plate rolling machine

.jpg)