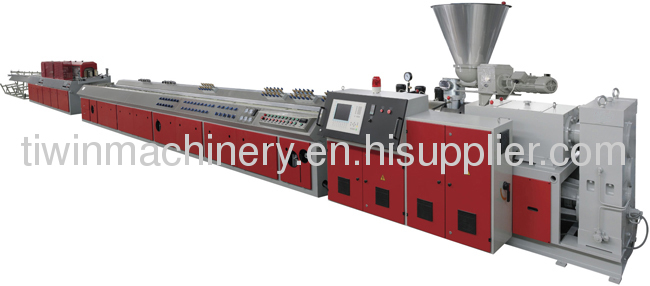

Plastic Profile Extrusion Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, negotiable, WU |

| Supply Ability: | 5 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plastic Profile Extrusion Line, Double Pipes Extrusion Line, XPS Heat Insulation Board Production Line, PVC Pipe Production Line, HDPE Pipe Production Line |

Product Detail

| Model No.: | TW65/28 |

|---|---|

| Means of Transport: | Ocean, Air, negotiable, Land |

| Brand Name: | Tiwin |

| Drive power: | 30KW |

| Max capacity: | 50-60KG/H |

| Production Capacity: | 5 sets per month |

| Packing: | flexible packaging |

| Delivery Date: | 60 workdays |

Product Description

Plastic Profile Extrusion Line

Application and Features WPC production line using a specially designed screw and barrel, die and extrusion machining production process to produce wood-plastic products. Product series:

One step wood&plastic thick plate extrusion

One step wood&plastic profile extrusion

One step wood&plastic decoration board extrusion

Wood&Plastic pelletizing

Wood&Plastic moulds

Extruder alone can extrude directly after twice mixing, or pelletize and extrude two steps. It saves electric power and space.

This line can produce PE, PP or PVC, wood&plastic profiles, which mainly used for trays, packing plate, flooring, outdor decorative materials, etc. Additive amount of wood powder and plant fiber is high (Max. 50%-75%). This equipment can also process and extrude PP, PE, PVC, ABS, PS, etc.

Main technical parameters

Single Screw | Conical Twin Screw | |||||||

Model | TW65/28 | TW90/28 | TW120/28 | TW65/132 | TW80/156 | TW92/188 | TW75/44 | TW92/44 |

Drive power (kw) | 30 | 55 | 90 | 37 | 55 | 110 | 75 | 132 |

Max Capacity (KG/H) | 50-60 | 80-100 | 150-200 | 120 | 280 | 350 | 300 | 500 |

Center height (mm) | 1050 | 1050 | 1050 | 1050 | 1050 | 1100 | 1050 | 1050 |

Weight (KG) | 1200 | 2000 | 4000 | 4000 | 5500 | 8000 | 5000 | 8800 |

.jpg)