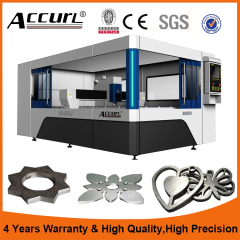

cnc glass cuting machine

10000.0~56650.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 50 Sets/Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Wood Pellet Mill, Wood Chipper, Windows And Doors Making Machine, Hammer, Mixer |

Product Detail

| Model No.: | BL-CNC-3725 |

|---|---|

| Means of Transport: | Ocean, Land |

| Condition: | Nwe |

| Brand Name: | SHARE |

| Cutting Precision: | 0.30mm |

| Voltage: | 380V,50Hz, 3Phase |

| Cutting Speed: | 100m/min |

| Dimension: | 4710*3250*930mm |

| weight: | 1500kg |

| Certification: | CE |

| Warranty: | one year |

| After-sales service provided: | Engineers available to service machinery oversea |

| Production Capacity: | 50 Sets/Month |

| Packing: | Packing in Plywood Case |

| Delivery Date: | One Month after P/O |

Product Description

CNC glass cutting machine:

1. CNC glass cutting machine Introduction

Mode: BL-CNC-3725

2. CNC glass cutting machine Technical Parameters

Power supply; 380V 50HZ

cutting speed; 100m/min

cutting precision; Straight line: 0.30mm Curve: 0.30mm

Max. size of glass; 3650mmX2750mm

Min. size of glass; 1000mmX1000mm

External dimension 4710×3250×930mm

Weight approx. 1500Kg

3. CNC glass cutting machine Prefomance features;

1). CNC series full-auto glass cutting product line is composed of three related single

machines, separately are "glass loading table", " CNC series full-auto cutting machine"

and " air cushion glass breaking table" Three equipments are centralized controlled by

the central control unit to combine a high efficiency and high precision glass cutting

2).The work flow is: after the glass loading machine starts, the suction pads arm will get the glass. Under the control of the sensor, the glass will look for the edge automatically in X and Y directions; after it will deliver the glass to NC cutter table after it moves to

designated position.

3). Under the guidance of laser sensory element, the mechanical- photoelectricity combined glass will localize and the cutting knife will move to origin of coordinates according to the instruction and start the auto cutting per preset graphic.

4). After the cutting is completed, the glass will be delivered to the glass breaking table via the conveyer; the glass will be broken after the roof bar is started. Thus the overall flow is finished.