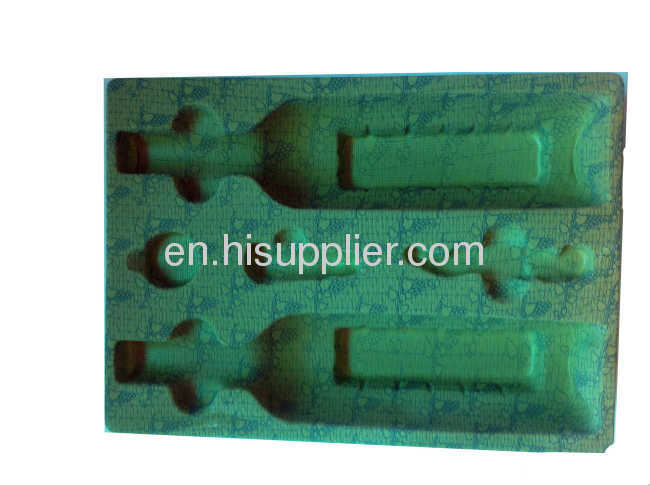

Thermo formed liner blister tray with flocking & velvet

| Min. Order: | 500 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 20000 pcs/ month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PS Sheets; Flocked Sheets In Different Materials; Various Type Vacuumforming Products; |

Product Detail

| Model No.: | HSL-HZ-12 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| High quality: | reasonable price |

| good after service: | Advanced production equipment |

| Fine workmanship of the employee: | Fast delivery time |

| Production Capacity: | 20000 pcs/ month |

| Packing: | carton box |

| Delivery Date: | 7-10days after confirmation |

Product Description

Plastic flocking blister packaging tray for cosmetic ,toy and handware

Flocking is a kind of special material, it feels soft. Usually we stick a layer of flocking to a rigid plastic board, then it becomes a flocing tray. Flocking could be used to promote the grade of the product packaged by it.

Product : | Plastic flocking blister packaging, blister tray |

Use : | Gift, Artware, Cosmetic, Food, Electronic, toy, tool packaging, etc. |

Material : | PVC , PET , PP , PS flocking |

Size : | As per client's demand ,and accept customized |

Color : | Any color |

MOQ : | 1000 PCS |

Sample time | 3-5 days |

Production ability : | 50000 pcs / Day |

Lead time : | 10-15 working days |

QC : | 3 times from materials selection, pre-production machines testing to finished goods |

Payment term : | T/T,Palpal ,western union,Money gram |

OEM : | Welcomed |

Packaging : | Inside plastic bag, outer paper carton packing. |

Certification : | ISO 9001:2000 / FDA TEST / ROHS / SGS |

our advantage:

1 Reliable and more professional.

2 Our professional engineer can make products and mould design by software CAD. UG. PROE and Solidwork according your request.

3 Made-to-order, completely customized, available for OEM/ODM sevice.

4 standard mould base, lower mold cost, we have own experienced mold technicians.

5 Send sample with test results to customers for checking.

6 the max size can reach 2500x1500x600mm, the thickness is 0.14-10mm, the precision can be reached 0.3MM.

7 Fabrication: Vacuum forming, CNC trimming and treament, engraving or silkscreen printing logos, polishing,spray paint , electroplate and scraping process etc.

8 Our plastic vacuum forming products are widely applied in toy, catering auto, mechanism, household appliance, tourism, printing, medical equipment, architecture, touring, advertising, furniture etc.