embossing silk vaccum form tray for glass bottle

| Min. Order: | 1000 pcs |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20000PCS/ DAY |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PS Sheets; Flocked Sheets In Different Materials; Various Type Vacuumforming Products; |

Product Detail

| Model No.: | HSL-YH-02 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

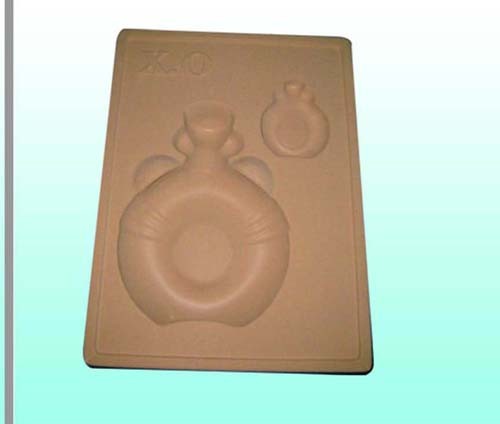

| Customized: | embosing ,silk screen,printable |

| Material: | Plastic |

| Process Type: | Blister,thermoforming packaging |

| Custom Order: | Accept |

| Usage: | beverage/wine/ |

| size&shape: | fully customize |

| Feature: | recyclable |

| Production Capacity: | 20000PCS/ DAY |

| Packing: | CARTON |

| Delivery Date: | 7-15 days after confirmation |

Product Description

embossing silk vaccum form tray

We are a manufacture specializing in thermoforming blister package,plastic gift box,tube box and plastic hanger card etc.

We provide customized service is make the package according to the design you provide to us , and we also have the one-shop service that we design and make the package for you uniquely according to the feauture of your products.we had been in the packaging field for 7years experience,we are using high-tech machines for prodction,our quality and price shall be very competitive.

1)clear display your product

2)high quality and good service

3)protect your product

4)more attractive

5)custom design and made

6)the price is just for your reference.

embossing silk vaccum form tray

C.About all the material types we use:

1.PVC:a.Advantages:the cheapest and very commen material.Very easy to be sealed by heat sealing machine and high frequency.

b.Disadvantage:not environmental and nonflammable.Once flambe,it will produce chloration,what will do bad to the environment.

2.PS:a.Advantage:very easy to be vacuum thermoformed and it is environmental material.Always molded into trays,including flocky trays.Widely used in electron,medical,food,cosmetic,hardware and so on.

b.Disadvantage:relatively speaking,it is a bit fragile and easy to be torn off.

3.PP:a.Advantage:high melting point and can be microwaveable.Widely used in food packaging.

b.Disadvantage:shrink material,not easy to be vacuum thermoformed;has not passed the Halogen Free test but it is food grade material.

4.PET:PET has two types,one is APET,the other is PETG.Both have high transparency and are environmental material.APET could not be sealed by our machine but PETG can.PETG is the only one which has passed the Halogen Free test.

flock vaccum wine bottle tray

flock vaccum wine bottle tray