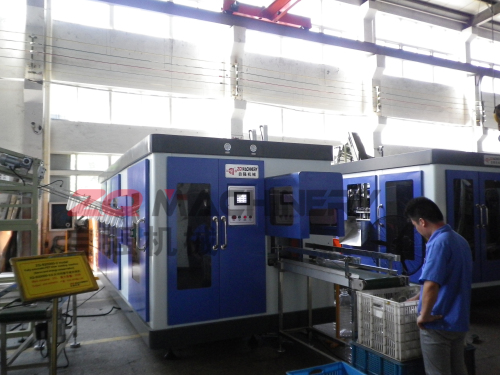

PET mineral water bottle manufacturing line with CE

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-B1500-6 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Auto Systems: | Full automatic |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

PET mineral water bottle manufacturing line

(Servo and energy conservation)

ZQ-B1500-8 Fully automatic PET stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has eight cavities and the maximum volume of the products is 2.0L.This model is especially applied in the bottle production of PET water,hot-filling juice/tea,carbonated drinks,edible oil,cosmetics,pesticide bottle,and other packing containers,which is made of plastic of crystalline type, such as PET and PP etc.

This machine adopts rotary perform loading system,which is very stable and reliable and applicable of different size of preform.

High Speed (Output MAX): 9000 Bottles/Hour, Container Volume: <=2000ml.

PET mineral water bottle manufacturing line

The advanced hydraulic mould clamping system helps the machine runs stablely with little vibration and applicable to different bottle sizes.

The servo conveying system with high accuracy of position,quick speed and good stability.

The precise design of heating tubes height and PET preforms spacing, to make it work the best.

The top class air supply control system assures even air flow and quick response of the machine ,which improves the quality and uniformity of the products.

PET mineral water bottle manufacturing line, info.

| TYPE | ITEM | ZQ-B1500-4 | ZQ-B1500-6 | ZQ-B1500-8 |

| CONTAINER | Number of cavity | 4 cavities | 6 cavities | 8 cavities |

| Output | 3800-4200 pcs/hr | 5500-6000 pcs/hr | 7000-9000pcs/hr | |

| Max.container volume | 2.0L | 2.0L | 2.0L | |

| Max.neck diameter | 38mm | 38mm | 38mm | |

| Max.container diameter | 110mm | 110mm | 110mm | |

| Max.container height | 300-330mm | 300-330mm | 300-330mm | |

| ELECTRICAL SYSTEM | Number of lamp | 40pcs | 40pcs | 40pcs |

| Max.heating power | 60kw | 60kw | 80kw | |

| Installation power | 68kw | 68kw | 88kw | |

| Actual power consumption | 35-40kw | 40-48kw | 60-65kw | |

| AIR SYSTEM | Operatating pressure | 7-9kg/cm² | 7-9kg/cm² | 7-9kg/cm² |

| Low pressure consuming | 2000Ltr/min | 3000Ltr/min | 4000Ltr/min | |

| Blowing pressure | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | |

| High pressure consuming | 3000-3500 Ltr/min | 4500-5000 Ltr/min | 6000-6500 Ltr/min | |

| CHILLER WATER | Operating pressure | 8-10 kg/cm² | 8-10 kg/cm² | 8-10 kg/cm² |

| Temperatuer | 10ºC | 10ºC | 10°C | |

| Consuming | 19000 kcal/hr | 25200 kcal/hr | 35000 kca/hr | |

| Flow rater | 60Ltr/min | 200Ltr/min | 250 Ltr/min | |

| MACHINE | Machine dimension | 4.9x2.2x2.2(m) | 5.5x2.2x2.2(m) | 7.5x2.2x2.2(m) |

| Machine weight | 5.0ton | 6.5ton | 8.0 ton |

Note: The specifications are subject to change without notice for the further improvement.

!Note: Custom production accepted. Any client idea tried.

ZQ Machinery