handled bottle stretch blow molding machine with CE

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-B2500-2 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Auto Systems: | Fully Automatic |

| Number of cavity: | 2 cavities |

| Output: | 900-1200bph |

| After-Sales Service Provided: | Engineers Available to Service Machinery Overseas |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

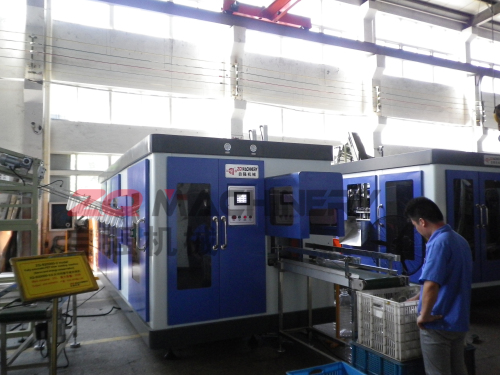

handled bottle stretch blow molding machine

ZQ-B2500-2 is our newly designed full automatic blow molding machine for handled bottle production,this model boasts with full automation,high intelligence,stable fuctioning,simple composition,high efficiency,low cost,no contamination in production,up to National Hygienic Standard,widely applied in food,beverage,cosmetics and pharmaceutical field,etc,especially find great applications in edible oil production industry.

In ZQ-B2500-2 blow molding machine operating,after preform being loaded and positioned ,with the help of sevo motor positioning device,handles can be accuratedly positoned in mold, and realizes full automatic production for handle bottles.

Handled bottle blow molding machine substantially increase production output without more labor cost,bringing great significance to PET edible oil bottle blow molding machine industry,a good option for medium–large manufacturers for handled bottle with high output demands,however,for those with small output requirements,ZQ semi-automtic blow molding machine (ZQ22-III,ZQ22-IV) would be a good choice!

handled bottle stretch blow molding machine,Information.

| TYPE | ITEM | ZQ-B2500-2 |

| CONTAINER | Number of cavity | 2cavities |

| Output | 900-1200 pcs/hr | |

| Max.container volume | 2.5L | |

| Max.neck diameter | 12-38mm | |

| Max.container diameter | 125mm | |

| Max.container height | <350mm | |

| ELECTRICAL SYSTEM | Number of lamp | 40pcs |

| Max.heating power | 60kw | |

| Installation power | 65kw | |

| Actual power consumption | 32-38.4kw | |

| AIR SYSTEM | Operatating pressure | 8-10kg/cm² |

| Low pressure consuming | 2000-3000Ltr/min | |

| Blowing pressure | 26-35kg/cm² | |

| High pressure consuming | 3600-4200 Ltr/min | |

| CHILLER WATER | Operating pressure | 3-4 kg/cm² |

| Temperatuer | 18ºC | |

| Consuming | 16000kcal/hr | |

| Flow rater | 135Ltr/min | |

| MACHINE | Machine dimension | 4.05x2.80x2.50(m) |

| Machine weight | 4.0ton |

Note: Custom production accepted. Any client idea tried.