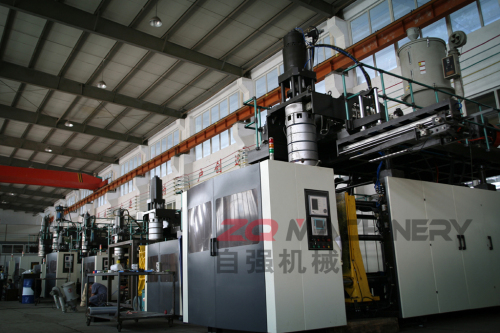

pe&pp container extrusion molding machine with CE

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQB-90 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Warranty: | 12 Months |

| Delivery Date: | 50 Days |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 45 Days |

Product Description

pe&pp container extrusion molding machine

The 25-160L drums, tool boxes and auto parts series consists of ZQB-80,ZQB-90,ZQB-100 and ZQB-120 etc., which can be used for producing drums, tool boxes and hollow parts of all kinds. Materials of PE, PP, and ABS can be used. Maximum capacity of accumulator head can be 12L while volume of products can be 160L. Its control system adopts closed loop control imported from Europe and hydraulic system is pressure-flow double proportional control equipped with variable plunger pump to ensure fast and smooth operation of the machine and energy consumption of the hydraulic system can be reduced by 30% or above, saving considerable electricity.

pe&pp container extrusion molding machine

| Specification | ZQB80 | ZQB90 | ZQB100 | ZQB120 | |

| Material | PE\PP… | PE\PP… | PE\PP… | PE\PP… | |

| Max.container capacity | L | 25 | 50 | 120 | 160 |

| Number of die | set | 1 | 1 | 1 | 1 |

| Output | pcs/hr | 500 | 400 | 360 | 300 |

| Machine Dimension | m | 4.2×2.3×3.6 | 4.6×2.5×3.8 | 5.8×2.5×4.6 | 6.9×2.9×4.8 |

| Total weight | ton | 12 | 13.8 | 18 | 20 |

| Accumulator head | ZQB80 | ZQB90 | ZQB100 | ZQB120 | |

| Accumulator capacity | L | 5 | 6.6 | 12 | 18 |

| Power of die heating | KW | 18 | 22 | 26 | 38 |

| Number of heating zone | zone | 4 | 4 | 4 | 5 |

| Die diameter | mm | 300 | 350 | 450 | 510 |

| Injection pressure | Mpa | 8 | 8 | 8 | 8 |

| Max.injection speed | Kg/sec | 1.5 | 1.5 | 1.5 | 1.5 |

| Clamping Unit | ZQB80 | ZQB90 | ZQB100 | ZQB120 | |

| Clamping force | KN | 210 | 350 | 500 | 720 |

| platen opening stroke | mm | 250-700 | 400-1000 | 500-1400 | 600-1400 |

| platen size | mm | 740×600 | 880×780 | 1020×1060 | 1100×1200 |

| Max mould size | mm | 560×630 | 700×960 | 800×1260 | 900×1400 |

| Mould thickness | mm | 250-350 | 455-510 | 360-700 | 450-750 |

| Extruder Unit | ZQB80 | ZQB90 | ZQB100 | ZQB120 | |

| Screw diameter | mm | 80 | 90 | 100 | 120 |

| Screw L/D ratio | L/D | 25:1 | 30:1 | 30:1 | 30:1 |

| Extruding Volume | Kg/hr | 100-120 | 120-200 | 180-270 | 200-320 |

| Screw rotation rate | r/min | 10-86 | 10-86 | 10-86 | 10-86 |

| Extruder heating power | KW | 20.2 | 21.6 | 26 | 32 |

| Extruder driving power | KW | 30 | 37 | 45 | 45 |

| Power consumption | ZQB80 | ZQB90 | ZQB100 | ZQB120 | |

| Driving power | KW | 52 | 76 | 89 | 130 |

| Heating power | KW | 36 | 44 | 60 | 78 |

Note: The specifications are subject to change without notice for the further improvement.

!Note: Custom production accepted. Any client idea tried. pe&pp container extrusion molding machine

plastic cosmetic bottles extrusion blow mold machine