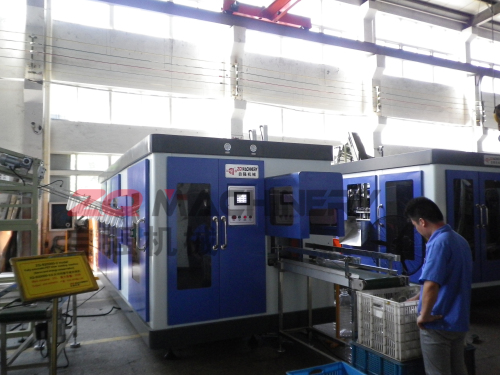

extrusion plastic bottle blowing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQS-10L |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Max Volume: | 10 liter |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 45 Days |

Product Description

extrusion plastic bottle blowing machine

The 16L single-station automatic blow moulding machines include four series of ZQS-2L, ZQS-5L,ZQS-10L and ZQS-16L. The Machine is a single station machine, and suitable for producing high quality container with medium output. It specializes in the manufacture of PE\PP\PVC\TPU\PETA containers of up to 16L, with from one to six fold diehead, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals,food, toys and auto-parts. The clamping system is a high-precision single-station linear guide, extrusion system using a hard gear reducer and inverter imported from Japan.The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve. The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical parts.

extrusion plastic bottle blowing machine

Clamping---------Single station+Hight-precision guide+large arm cylinder axle

Extrusion system--Hard gear surface reducer+Japan inverter

Die system--------Central-incoming extrusion die with special steel

Hydraulic system--Japan hydraulic valve seal and proportional control

Control system----Japan PLC+Imported HMI+PLC automatic

Specification | ZQS-2L | ZQS-5L | ZQS-10L | ZQS-16L | |

Material | PE\PP… | PE\PP… | PE\PP… | PE\PP… | |

Max.container capacity | L | 2 | 5 | 10 | 16 |

Number of die | set | 1\2\3\4 | 1\2\3\4 | 1\2\3\4 | 1\2\3\4 |

Output | pcs/hr | 1400 | 1000 | 800 | 700 |

Machine Dimension | m | 2.5×1.6×2.4 | 2.9×1.85×2.4 | 4.2×2.95×3 | 4.8×3.2×3.1 |

Total weight | ton | 3 | 4.5 | 6 | 7 |

Accumulator head | ZQS-2L | ZQS-5L | ZQS-10L | ZQS-16L | |

Number of die heating | zone | 3 | 3 | 3 | 4 |

Power of die heating | KW | 4.2 | 5.8 | 6-7 | 6-7 |

Max die-pin diameter | mm | 60 | 80 | 140 | 140 |

Center distance of twin-die | mm | 130 | 160 | 240 | 260 |

Center distance of tri-die | mm | 85 | 110 | 160 | 180 |

Center distance of four-die | mm | 65 | 85 | 120 | 130 |

Clamping Unit | ZQS-2L | ZQS-5L | ZQS-10L | ZQS-16L | |

Clamping force | KN | 38 | 70 | 110 | 155 |

platen opening stroke | mm | 135-370 | 145-510 | 230-600 | 230-600 |

platen size | mm | 280×380 | 320×390 | 450×490 | 500×490 |

Max mould size | mm | 300×320 | 350×370 | 520×500 | 600×500 |

Mould thickness | mm | 135-210 | 155-300 | 235-380 | 235-380 |

Extruder Unit | ZQS-2L | ZQS-5L | ZQS-10L | ZQS-16L | |

Screw diameter | mm | 50 | 60 | 70 | 75 |

Screw L/D ratio | L/D | 24:1 | 24:1 | 24:1 | 25:1 |

Extruding Volume | Kg/hr | 30-50 | 60-80 | 100-120 | 100-130 |

Number of heating zone | zone | 3 | 3 | 3 | 4 |

Extruder heating power | KW | 3-4.4 | 5-6.6 | 6-8.2 | 7.3-8.6 |

Extruder driving power | KW | 5.5 | 15-18.5 | 22-30 | 22-30 |

extrusion plastic bottle blowing machine

ZQ Machinery

.jpg)

.jpg)