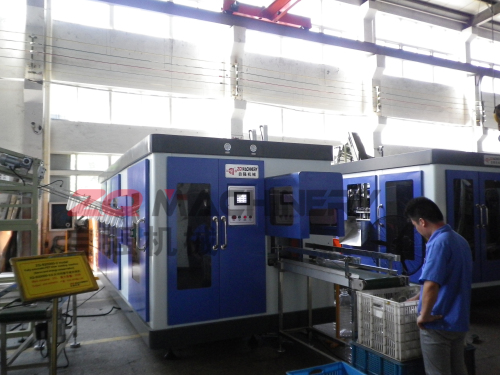

plastic pet water bottle production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-B600-8 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Auto Systems: | Fully Automatic |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

plastic pet water bottle production line

ZQ-B600-8 Full-automatic PET stretch blowmolding machine is the most stable two-step automatic stretch blow mouldingmachine. It has eight cavities and the maximum volume of the products is 600ml.It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics,wide-mouth, hot filling, and other packing containers, which is made of plasticof crystalline type, such as PET and PP etc.

plastic pet water bottle production line

ZQ-B600-8 machine adopts intermittent preform loadingsystem.

High Speed (Output MAX): 11000 Bottles/Hour, Container Volume:<=600ml.

| TYPE | ITEM | ZQ-B600-8 |

| CONTAINER | Numberof cavity | 8 cavities |

| Output | 9000-11000 pcs/hr | |

| Max.container volume | 0.6L | |

| Max.neck diameter | 28-30mm | |

| Max.container diameter | 60mm | |

| Max.container height | 260mm | |

| ELECTRICAL SYSTEM | Numberof lamp | 48pcs |

| Max.heating power | 48kw | |

| Installation power | 56kw | |

| Actual power consumption | 45kw | |

| AIR SYSTEM | Operatatingpressure | 7-8kg/cm² |

| Low pressure consuming | 2000Ltr/min | |

| Blowing pressure | 25-35kg/cm² | |

| High pressure consuming | 2300-2500 Ltr/min | |

| CHILLER WATER | Operatingpressure | 5-6 kg/cm² |

| Temperatuer | 10°C | |

| Consuming | 8000kcal/hr | |

| Flow rater | 200Ltr/min | |

| MACHINE | Machinedimension | 6.9x2.2x2.1(m) |

| Machine weight | 6.5ton |

Machine advantages

1.This machine is easy to operate by using fullautoamtic human-machine interface. It runs smoothly at very high speed.

2.Every parts of whole machine is selected properly and treated precisely.

3.It adopts advanced intermittent preform loading syestem.

4.Conveyingpreforms automatically with conveyor.

5.Strong penetrability and good andswift distribution of the heat by letting the bottles rotate by itself andrevolute in the rails simultaneously in the infrared preheater.

6.Highadjustability to enable the preheater to preheat preforms in shapes by adjustingthe light tube and the length of the reflecting board in the preheating area,and eternal temperature in the preheater with an automatic thermostaticapparatus.

7.High safeties with security automatic-locking apparatus ineach mechanical action, which will make the procedures turn into a state ofsafety in case of a breakdown in certain procedure.

8.No contamination andlow noise.

9.Satisfaction with different atmospheric pressure for blowingand mechanical action by dividing the blowing and action into three parts in theair pressure diagram of the machine.

10.Strong clamping force with highpressure and double crank links to lock the mold.

11.Two ways of operating:automatic and manual.

12.Safe,reliable,and unique design of the position ofvalve to make the air pressure diagram of the machine easier tounderstand.

13.Low cost, high efficiency, easy operation, easy maintenance,etc, with automatic technological process.

14.Contamination is avoided forthe bottle body.

15.Ideal effect of the chilling with the chillingsystem.

16.Easy installation and starting;Low rejection rate: less than 0.2percent.

plastic pet water bottle production line

ZQ Machinery