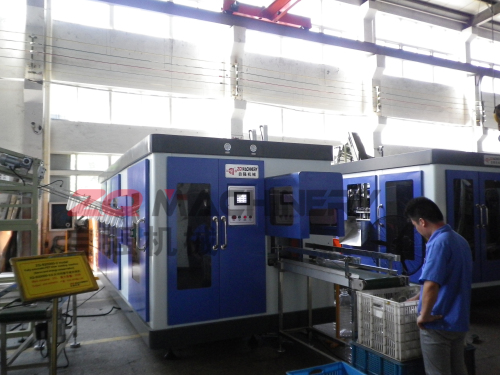

pet bottle moulding machine manufacturing line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-B5000-2 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

pet bottle moulding machine manufacturing line

ZQ-B series full-automatic pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has one to six cavities and the maximum capacity of the products is 0.6L,2.0L,5L and 10L. It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

Machine advantages

1).High Automatization

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4).High Speed:1400BPH(1-cavity) 8000BPH(6-cavity).

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

pet bottle moulding machine manufacturing line

| TYPE | ITEM | ZQ-B5000 | ZQ-B5000-2 | ZQ-B5000-4 |

| CONTAINER | Number of cavity | 1cavities | 2cavities | 4cavities |

| Output | 650-800 pcs/hr | 1200-1500 pcs/hr | 2000-2200 pcs/hr | |

| Max.container volume | 5L | 5L | 5L | |

| Max.neck diameter | 45-80mm | 45-80mm | 45-80mm | |

| Max.container diameter | 180mm | 180mm | 180mm | |

| Max.container height | 350mm | 350mm | 350mm | |

| ELECTRICAL SYSTEM | Number of lamp | 24pcs | 36pcs | 60pcs |

| Max.heating power | 22kw | 36kw | 60kw | |

| Installation power | 22kw | 60kw | 100kw | |

| Actual power consumption | 18kw | 22kw | 36kw | |

| AIR SYSTEM | Operatating pressure | 7-9kg/cm² | 7-9kg/cm² | 7-9kg/cm² |

| Low pressure consuming | 1200Ltr/min | 1600Ltr/min | 2600Ltr/min | |

| Blowing pressure | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | |

| High pressure consuming | 1200-1600 Ltr/min | 2600-3000 Ltr/min | 4500-5000 Ltr/min | |

| CHILLER WATER | Operating pressure | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² |

| Temperatuer | 10ºC | 10ºC | 10ºC | |

| Consuming | 3600kcal/hr | 4600kcal/hr | 6600kcal/hr | |

| Flow rater | 20Ltr/min | 30Ltr/min | 45Ltr/min | |

| MACHINE | Machine dimension | 3.0x2.1x2.1(m) | 4.3x2.1x2.1(m) | 5.6x2.1x2.1(m) |

| Machine weight | 2.3ton | 4.0ton | 5.5ton |

Note: The specifications are subject to change without notice for the further improvement.

pet bottle moulding machine manufacturing line

ZQ Machinery