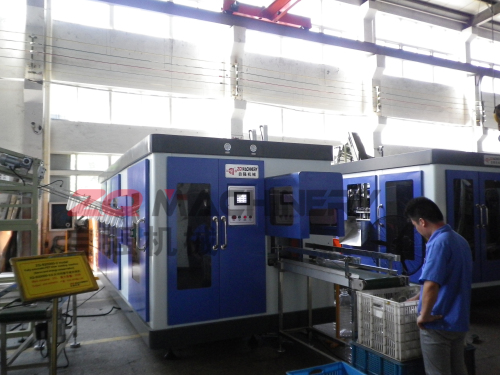

plastic bottle blowing moulding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-A600-1 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

plastic bottle blowing moulding machine

ZQ-A series, Automatic Stretch Blowing Machine With Preform Manual Loading

ZQ-A series, newly developed by our company, is a two-step automatic blow-molding machine, which requires labor to put performs into the preheater only. ZQ-A series is of one cavity and the maximum cavity of the bottles is 0.6L,2.0L,5L. It can blow various bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET, PP etc.

Compared with other full-automatic series, ZQ-A series has no automatic conveyer, so it can't transfer performs automatically, but requires labors to put performs into preheater. The distinctive feature of the ZQ-A is as follows: it has saved the cost to the maximum extent; it has lower rejection rate, higher production, and more stable performance than the semi-automatic one, and moreover, it is easy to run. Therefore, it will take the place of the semi-automatic blow-molding machine.

plastic bottle blowing moulding machineTYPE ITEM ZQ-A600 ZQ-A600-2 ZQ-A600-3 CONTAINER Number of cavity 1 2 3 Output 1100-1400 pcs/hr 1700-2300 pcs/hr 3000-3300 pcs/hr Max.container volume 0.6L 0.6L 0.6L Max.neck diameter 38mm 38mm 38mm Max.container diameter 60mm 60mm 60mm Max.container height 260mm 260mm 260mm ELECTRICAL SYSTEM Number of lamp 14pcs 28pcs 32pcs Max.heating power 9kw 22kw 32kw Installation power 12kw 25kw 35kw Actual power consumption 9kw 14kw 20kw AIR SYSTEM Operatating pressure 7kg/cm² 7kg/cm² 7kg/cm² Low pressure consuming 800Ltr/min 1000 Ltr/min 1200 Ltr/min Blowing pressure ≤30kg/cm² ≤30kg/cm² ≤30kg/cm² High pressure consuming 1200-1600Ltr/min 1500-2000Ltr/min 2000-2500Ltr/min CHILLER WATER Operating pressure 5-6 kg/cm² 5-6 kg/cm² 5-6 kg/cm² Temperatuer 10°C 10°C 10°C Consuming 3600kcal/hr 5600kcal/hr 7600kcal/hr Flow rater 20Ltr/min 30Ltr/min 40Ltr/min MACHINE Machine dimension 2.5×1.4×1.7(m) 2.9×1.55×1.8(m) 3.4×1.4×1.8(m) Machine weight 1.5T 1.6T 1.9T

Note: The specifications are subject to change without notice for the further improvement.

Machine settings

a).PLC colour display: OMRON(JAPAN)

b).Pneumatic parts:AIRTAC(TAIWAN)

c).Controller of preform transfer:Servo motor DELTA(TAIWAN)

d).Other electric parts are all world-famous brand

ZQ Machinery