rotary stretch blow molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Blow Molding Machine, Blow Moulding Machine, Blowing Machine |

Product Detail

| Model No.: | ZQ-R12 |

|---|---|

| Means of Transport: | Ocean, Land |

| Trademark: | ZQ |

| Certificates: | CE,ISO9001:2008 |

| Production Capacity: | 30 Sets/Month |

| Packing: | General Packing |

| Delivery Date: | 40 Days |

Product Description

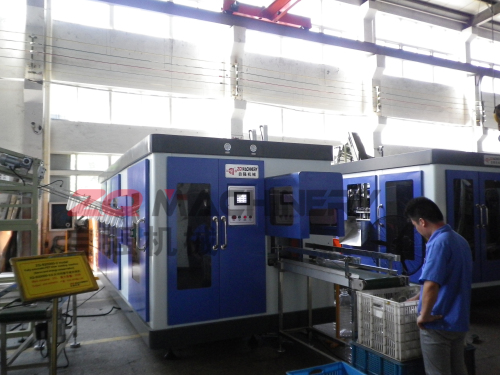

rotary stretch blow molding machine

ZQ-R Series is the most stable two-step fully automatic pet stretch blow molding machine. It has ten cavities and the maximum capacity of the products is 2.0L. It can blow bottles in shapes: carbonated,mineral,pesticide,cosmetics,hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET, PP etc.

High capability/price ratio PET processing machines are praised as reliable products by our customers. The automatic blowing machine series have powerful productivity but with very reasonalbe price.

Advantages

1.Rotary blowing method with high efficiency and output speed to reach 99.5% productivity

2.SIEMENS electric control system with quick action and high accuracy

3.German imported air-valve, cylinder, SEW brand motor and trequency-transfer applied to keep stable operation and stretch

4.Quick mould exchanging system makes mould changing easily

5.Professionally designed robot sends preform and takes bottle out automatically and accurately

6.PHILIPS infrared ray lamps with automatic feedback compensation applied in heating system for bearing of heat and keeping heating steady

rotary stretch blow molding machine

| TYPE | UNIT | ZQ-R4 | ZQ-R6 | ZQ-R8 | ZQ-R10 | ZQ-R12 |

| Speed | pcs/h | 4000-5500 | 6600-9000 | 8800-12000 | 9000-13000 | 14400-21600 |

| Bottle Volume | L | <=2.0L | <=2.0L | <=2.0L | <=2.0L | <=2.0L |

| Cavity | 4 | 6 | 8 | 10 | 12 | |

| Product Material | PET | PET | PET | PET | PET | |

| Max. Diameter of Product | mm | 120 | 120 | 120 | 120 | 120 |

| Max. Bottle Neck Diameter | mm | 38 | 38 | 38 | 38 | 38 |

| Max. Product Height | mm | 350 | 350 | 350 | 350 | 350 |

| Power Supply | 380V,50HZ | 380V,50HZ | 380V,50HZ | 380V,50HZ | 380V,50HZ | |

| Main Motor Power | KW | 6 | 4 | 4 | 6 | 6 |

| Oven Installation Power | KW | 80 | 110 | 140 | 170 | 216 |

| Elevator Power | KW | 2 | 2 | 2 | 2 | 2 |

| Blowing Air Pressure | Mpa | 3.0-4.0 | 3.0-4.0 | 3.0-4.0 | 3.0-4.0 | 3.0-4.0 |

| Blowing Air Flux | m3/min | 8-12 | 8-16 | 8-16 | 16-24 | 16-30 |

| Working Air Pressure | Mpa | 1 | 1 | 1 | 1 | 1 |

| Working Air Flux | m3/min | 2 | 3.5 | 3.5 | 3.5 | 7 |

| Dimension of machine | m | Machinery 3.2*2.4*2.2 | Machinery 2.1*2.9*3.1 | Machinery 2.1*2.9*3.1 | Machinery 3.2*2.5*3.3 | Machinery 2.3*3.2*3.1 |

| Oven 3.0*2.1*2.2 | Oven 3.5*0.9*2.6 | Oven 3.5*0.9*2.6 | Oven 5.0*2.2*3.3 | Oven 3.9*1.0*2.0 | ||

| Weight of machine | Ton | 6 | 7.5 | 10 | 16 | 17 |

| Eligible Rate | >=99.8% | >=99.8% | >=99.8% | >=99.8% | >=99.8% |

Note: The specifications are subject to change without notice for the further improvement.

ZQ Machinery

.jpg)