High Quality Insert Ball Bearing

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2,000,000 pcs/year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Changzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Deep Groove Ball Bearing, Self-aligning Ball Bearing, Steel Ball, Bearing Ring |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | OEM |

| Material: | chrome steel GCr15 / stainless stell |

| Precision Rating: | P0 (ABEC1), P6 (ABEC3), P5 (ABEC5) |

| Free Sample: | available |

| Seals Type: | open;ZZ; 2RS; Z; RS |

| Production Capacity: | 2,000,000 pcs/year |

| Packing: | 1.industrial standard packing 2.polybag+box+packing 3.as your order |

| Delivery Date: | 15 to 30 days |

Product Description

Specifications

1. Vibration level meet Z1 group and Z2 group

2. Low vibration and noise

3. High precision rotating

4. Low friction torque and high speed running

5. Acid-proof and alkali-proof

6.Can bear the corrosive and work in corrosion medium such as sea water, river aqua, distilled water, spare nitric acid, maritime climate, steam and so on

7. Can work in the high or low temperature environment within the scope of -253°C--350°C temperature usage

8. Series:UCP series, UCF series, UCFL series, UCFA series, HC series, ER series,SER series,UCC series

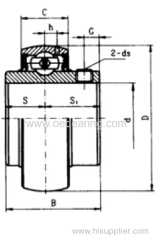

The internal structure of the insert ball bearing is the same with that of deep groove ball bearing. But the inner race of this bearing is wider than the outer race. The outer race has the spherical surface.

Insert ball bearings can self aligning with the fit between the outer race and the bearing block. Insert ball bearings are compact.

It's easy for loading and unloading. Spherical insert ball bearings often used in mining, metallurgy, textile, transportation machinery, etc.

Application

Insert Bearings are designed in almost the same way as deep groove ball bearings, except that the outer ring is spherical. Their design allows the bearings to be easily mounted in a housing block and be self-aligning. Widely used in mines, metallurgy, reaper, textile machinery, body building equipments, motors, chain belts, chain wheels, and automobile series, SALF series, UCT series, SBFL series etc

QC Procedure

1. Inspection and selection during each process

2. Assembly

3. Deviation test

4. Cleaning

5. Rotary test

6. Greasing

7. Noise inspection

8. Appearance inspection

9. Anti-rust treatment

10. Packaging

11. Third party pre-shipment inspection