galena lead ore concentration equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200 sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

| Main Products: | JIGGER, MAGNETIC SEPARATOR, FLOATATION SEPARATOR , BALL MILL, AMALGAMATION BARREL |

Product Detail

| Model No.: | JT1515/2 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Forui |

| color: | green, blue |

| treatment capacity(t/h): | 15-25 |

| water consumption(t/h): | 20-30 |

| power(kw): | 8 |

| stroke (mm): | 0-50 |

| Production Capacity: | 200 sets/month |

| Packing: | naked packing in container |

| Delivery Date: | in 30 working days after receipt of deposit |

Product Description

The composition of galena is PbS with its good floatability and specific gravity of 7.4-7.6. So the beneficiation of galena lead ore is floatation separation and gravity separation. Floatation separation makes use of its floatability to get high grade galena concentrate. Floatation beneficiation processing can help to get high enrichment efficiency, but it requires much about the operator with its high plant investment and high operation cost. However, floatation separation can be unfriendly to environment and it has been limited by government, and it will be taken place by gravity separation. Gravity separation has a low requirement about the operator with its small plant investment, and low operation cost. With reasonable plant allocation, the beneficiation efficiency of gravity separation is even better than floatation separation. So galena lead ore gravity upgrading will be the leading beneficiation method instead of floatation separation.

Galena gravity upgrading works greatly to gain high grade galena lead concentrate on basis of big specific gravity difference between galena and its gangue. The crude galena is crushed and screened to make the galena granules liberated from its gangue. Kind of gravity separators like jigging machine can be used to purify the galena to get galena concentrate and tailings. Machines like crushers, rod mills, jig separators, shaking tables can be involved in galena gravity processing flow sheet. The simple crushing breaks the big blocks into small ones while rod mill, as kind of milling equipment, is used to mill the crushed output to be fine of -5mm without any extensive-milling. Galena lead jig machine can be involved to enrich the milled galena to get the final concentrate and tailings. There shall be some fine granules in the tailings from jigger, so a shaking table can be used to recover the galena in the tailings to improve the recovery.

Forui is a manufacturer of kinds of mining machines for beneficiation of placer gold, quartz gold, mercury, barite, fluorite, celestite, pyrite, hematite, manganese, and recovering of smelting alloy from smelting slag of silica-manganese smelting slag, chromite smelting slag, and ferro-nickel smelting slag. Free test can be done for you if samples of 10-20 kgs can be available.

Illustration:

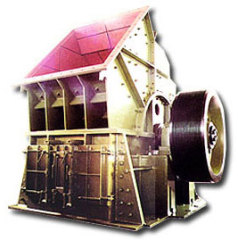

Saw-tooth-wave jigger of JT series is driven by saw-tooth wave and works by rising up and down water-stream

uniformity & serrated. It works greatly for ore/slag material of thin granularity size. It is widely used

in beneficiation of kinds of metal & non-metals & smelting slag like tungsten, tin, gold, iron, manganese, titanium,

chromium, sulfur, silica-manganese slag, ferro-manganese slag, ferro-nickel slag etc.

Working Principle:

JT jigger is kind of down-moving saw-tooth-wave jigger. Magnetic reduce motor drives the saw-tooth-wave producer

to make different-heart movement through the cam. And the adjustment device will be driven to do alternate motion

to make hypocentrum produce the regulation motion to squeeze the water in box move. The water-flow moving

goes through the screen to dash the bed stones and the ore to move along parabola. Then the ore will be fed

at the feeding port. The dropping speed differs for materials with different density to form different layers naturally.

The light material will be discharged by the dashing of water while the heavy material will go down through

the bed stones to the hypocentrum. Finally, the concentrate will be discharged to finish the jigging.

Merits:

1) water-recycling & low power

2) semi-automatic & easy to operate

3) continuous working & environment-friendly

4) quality & service-guaranteed

5) seaworthy & durable

Technical Parameter:

Model | Stroke | Stroke | Stroke | Feeding | Handling | Water | Power |

JT1515/2 | 0.47 | 0-25 | 0-150 | 8 | 15-25 | 30-50 | 8 |