Block 40H NdFeB magent Zn used in industral

1.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 ton/ year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | NdFeB Irregular Shape Magnet, Permanent NdFeB Cylinder Magnet, Permanent NdFeB Motor Magnets, Permanent NdFeB Block Magnet, Countersunk Hole Magnet Motor Magnet |

Product Detail

| Model No.: | N/M/H/SH/UH/EH/AH |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Industrial Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | Ningbo Xinqi Magnet |

| Material: | NdFeB Magnet |

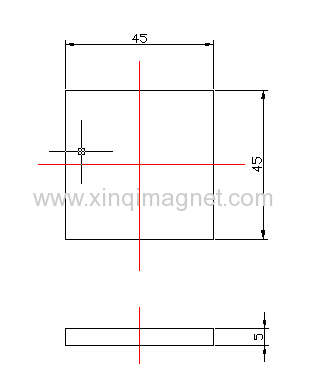

| Tolerance:: | +/-0.1 |

| Coating:: | Zn |

| Resistance:: | Excellent Against Salt Spray |

| Production Capacity: | 1000 ton/ year |

| Packing: | standard export sea or air packing |

| Delivery Date: | 15-20days |

Product Description

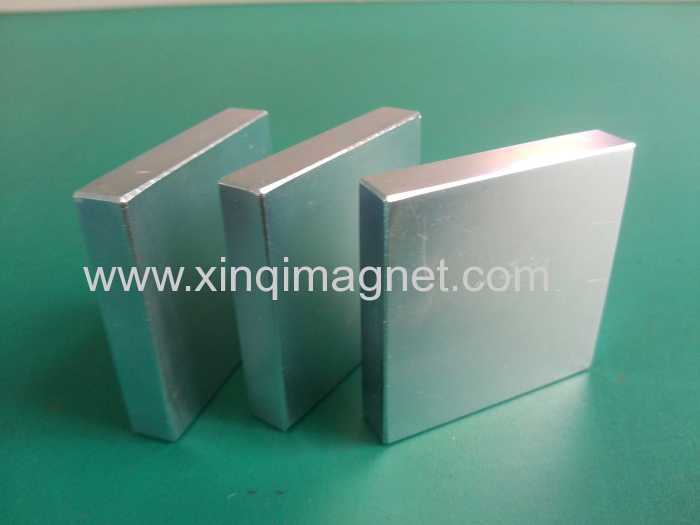

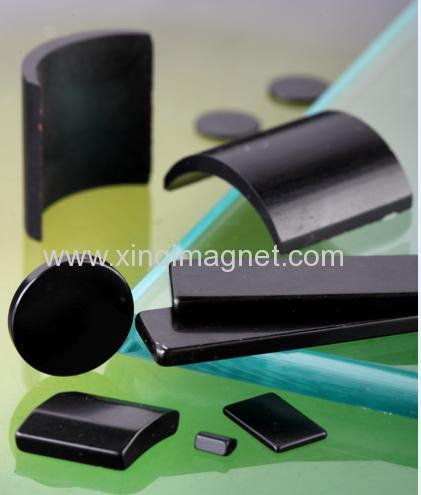

The picture of the products

Features:

1) This disc NdFeB magnet widely used in industy.

2) Coating:Zn

3) Zn plated is excellent against salt spray

Drawing of 40H NdFeB block magnet

Packing:

Inner packing: small white box, place plastic between magntes to avoid breaking.

Outer packing: Carton with OPP bag

Properties:

| (Hcb) | (Hcj) | (BH)max | Max Working | ||||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | Tempt(TW)℃ |

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1380 | 13.2-13.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1380-1420 | 13.8-14.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1400-1450 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 | 80℃ |

| N52 | 1430-1480 | 14.3-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 398-422 | 50-53 | 100℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100℃ |

| 45M | 1320-1380 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100℃ |

| 48M | 1370-1430 | 13.7-14.3 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | 100℃ |

| 50M | 1400-1450 | 14.0-14.5 | ≥1033 | ≥13.0 | ≥1114 | ≥14 | 382-406 | 48-51 | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1360 | 13.2-13.6 | ≥963 | ≥12.1 | ≥1353 | ≥17 | 326-358 | 41-46 | 120℃ |

| 48H | 1370-1430 | 13.7-14.3 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | 150℃ |

| 35SH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2=12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | 150℃ |

| 40SH | 1250-1280 | 12.5=12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150℃ |

| 42SH | 1280-1320 | 12.8=13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | 150℃ |

| 45SH | 1320-1380 | 13.2=13.8 | ≥1003 | ≥12.6 | ≥1592 | ≥20 | 342-366 | 43-46 | 180℃ |

Performance Range of Magnets

Br: from 12.500 Gauss to 12.800 Gauss

Hcj: 17kOe above

BH (max): from 38MGOe to 41MGOe

Max working tempt: 120°C

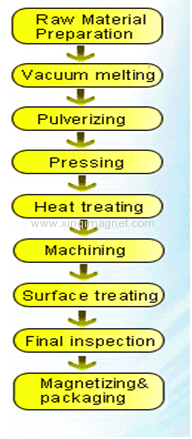

Production Process

The other products of our company

We provide different grades( from high to low performance) magnets and offer varieties of magnets in different shapes according to customers' design.

All our manufacturing procedures are operated well under ISO9001 and TS/16949