Rare Earth Segment 35SH motor magnet

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000ton/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | NdFeB Irregular Shape Magnet, Permanent NdFeB Cylinder Magnet, Permanent NdFeB Motor Magnets, Permanent NdFeB Block Magnet, Countersunk Hole Magnet Motor Magnet |

Product Detail

| Means of Transport: | Express Way, Ocean, Air |

|---|---|

| Application: | Motor Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | Xinqi |

| Permanent magnet: | NdFeB magnet |

| Shape: | Segment/Tile/Arc |

| Grade: | 38SH |

| Material: | Neodymium Iron Boron |

| Coating: | Nickle/Zink/Epoxy |

| Place of origin: | Ningbo |

| Magnetized: | Through thickness |

| Lead time: | 15-20days |

| Application: | motor |

| Plating thickness: | 10-20um |

| Production Capacity: | 1000ton/year |

| Packing: | standard export sea or air packing |

| Delivery Date: | 15-20days |

Product Description

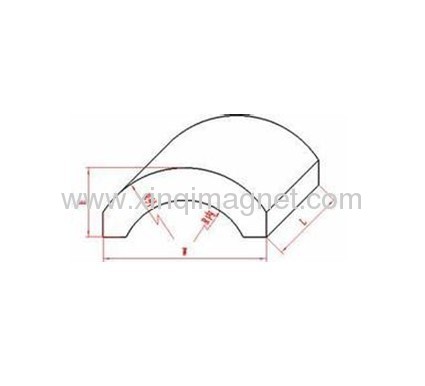

Small Segment 35SH motor magnet

Our factory is specialized in presicion magnets, our advantage is tight tolerance, dificult shape, high grade.

This product is segment motor magnet, most of motor magnets are segment shape, they can form a circle.

And have requirement of tempeture, so this one working temperature is 150℃, so we choose 35SH material.

Manufacturing Process of Rare Earth Neodymium Magnets

Neodymium, Iron, Boron and a few transition metals will be made into the NdFeB (Neodymium) powder, then fine NdFeB powder will be compacted in a die and sintered, fusing the powder into a solid material. There are 2 forms of pressing: die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances.

Machining & Tolerance of Rare Eart Neodymium Magnets

NdFeB magnets must be machined using diamond-grinding techniques. Sometimes, machining operations may be performed on Neodymium (NdFeB) materials using carbide tools, but surface finishes thus obtained may be less than optimal. The Standard tolerances for NdFeB (Neodymium) magnets are +/- 0.1mm for ground dimensions, but we can do the most tight tolerance is +/-0.02mm.

Features:

1) Small Segment 35SH motor magnet

2) Size:R*r*H*W*L mm

3) Grade: 35SH

4) Coating: Nickle (thickness ≥15um)

5) Magnetized through diameter

6) ISO/TS16949 passed

Packing:

Inner packing: small white box

Outer packing: Carton with OPP bag

| 35SH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2=12.5 | ≥907 | ≥11.4 | 287-310 | 36-39 | |||

| 40SH | 1250-1280 | 12.5=12.8 | ≥939 | ≥11.8 | 302-326 | 38-41 | |||

| 42SH | 1280-1320 | 12.8=13.2 | ≥987 | ≥12.4 | 318-342 | 40-43 | |||

| 45SH | 1320-1380 | 13.2=13.8 | ≥1003 | ≥12.6 | 342-366 | 43-46 |

Application of Rare Earth Neodymium Magnets

Widely used in automobiles, mobile phones, digital cameras, jewelry, clothing, all kinds of hardware accessories, electrical, laser heads, toys, gifts, speakers, packing, leather goods, medical equipment and adverying, Switchboard, voice coil motors (VCM's) in hard disk drives, high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors, loudspeakers etc.

Certification: