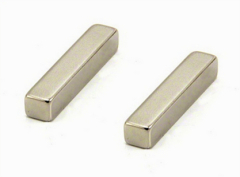

Alnico block shape magnets

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100ton/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | NdFeB Irregular Shape Magnet, Permanent NdFeB Cylinder Magnet, Permanent NdFeB Motor Magnets, Permanent NdFeB Block Magnet, Countersunk Hole Magnet Motor Magnet |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Application: | Motor Magnet |

| Shape: | Bar |

| Type: | Permanent |

| Composite: | AlNiCo Magnet |

| Brand Name: | XinQI |

| Alnico Block shape magnets: | Alnico block permant magnets |

| Coating thickness: | 10-20 um |

| Composition: | Neodymium |

| Lead time: | 15-20 days |

| Packing: | Box |

| Place of origin: | Ningbo |

| Surface: | Nickle |

| Certification: | ISO/TS16949 |

| Production Capacity: | 100ton/year |

| Packing: | Standard exporting package |

| Delivery Date: | 15-25days |

Product Description

Alnico block magnets

Features: LNG 16 Alnico Block magnets

1) This Alnico magnets used in motor.

2) Size: 10*8.5mm

3) Grade: LNG16

4) Special processing technic, .

5)Coating:None

6)ISO9001:2008; ISO/TS16949

Br | iHc | (BH)max | Tm | ρ | ||||

Grade | KGs | T | Koe | KA/m | MGOe | KJ/m3 | °C | ρ |

LN10 | 6000 | 0.600 | 0.500 | 40 | 1.20 | 9.6 | 400 | 6.9 |

ALNiCo1 | 7200 | 0.720 | 0.470 | 37.6 | 1.40 | 112 | 450 | 7.0 |

LNG12 | 7000 | 0.700 | 0.500 | 40 | 1.50 | 12.0 | 450 | 7.0 |

LNG16 | 7800 | 0.780 | 0.650 | 52 | 2.00 | 16.0 | 450 | 7.0 |

LNG34 | 12000 | 1.200 | 0.550 | 44 | 4.30 | 34.0 | 500 | 7.3 |

LNG37 | 12000 | 1.200 | 0.600 | 48 | 4.63 | 37.0 | 550 | 7.3 |

LNG26 | 10500 | 1.050 | 0.75 | 60 | 3.50 | 28.0 | 550 | 7.3 |

LNGT32 | 8000 | 0.800 | 1.25 | 100 | 4.0 | 32.0 | 550 | 7.3 |

LNGT38 | 8000 | 0.800 | 1.380 | 110 | 4.75 | 38.0 | 550 | 7.3 |

LNG44 | 12500 | 1.250 | 0.650 | 52 | 5.50 | 44 | 550 | 7.3 |

LNG52 | 13000 | 1.300 | 0.700 | 56 | 6.50 | 52 | 550 | 7.3 |

Packing:

Inner packing: small white box

Outer packing: Carton with OPP bag

Process flow:

casting: raw material---->vacuum melting ---->casting---->heating treating---->performance test---->last inspection----> packing

Sintering: raw material---->milling---->pressing--->Sintering-->heating treating---->performance test---->last inspection----> packing

Certification:

Alnico application places:Alnico products are mainly applied in auto parts, instruments and meters, electronic, electrical, teaching as well as aerospace, military and other fields has low temperature coefficient, high temperature resistant, resistant to moisture, it is not easy oxidation and the working stability is good wait for an advantag

company advantage:With production base as its reliance

With technological equipment as its support

With developing,producing and innovation as its basis

With processing autonomously as its guarantee

.jpg)