Neodymium Iron Boron magnet Special Block

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | Paypal, L/C, T/T |

| Supply Ability: | 800Tons/Year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | NdFeB Irregular Shape Magnet, Permanent NdFeB Cylinder Magnet, Permanent NdFeB Motor Magnets, Permanent NdFeB Block Magnet, Countersunk Hole Magnet Motor Magnet |

Product Detail

| Model No.: | 60*25*2mm |

|---|---|

| Means of Transport: | Express Way, Ocean, Air |

| Application: | Motor Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | Xinqi Magnet |

| Composition: | Neodymium |

| Grade: | 40SH |

| Surface treatment: | Nickle |

| Shape: | Irregular shape |

| Place of origin: | Ningbo |

| Lead time: | 15-20days |

| Coating thickness: | 10-20um |

| Certification: | ISO/TS 16949 |

| Packing: | In Cartons |

| Production Capacity: | 800Tons/Year |

| Packing: | box,carton,pallet |

| Delivery Date: | 10-25 days |

Product Description

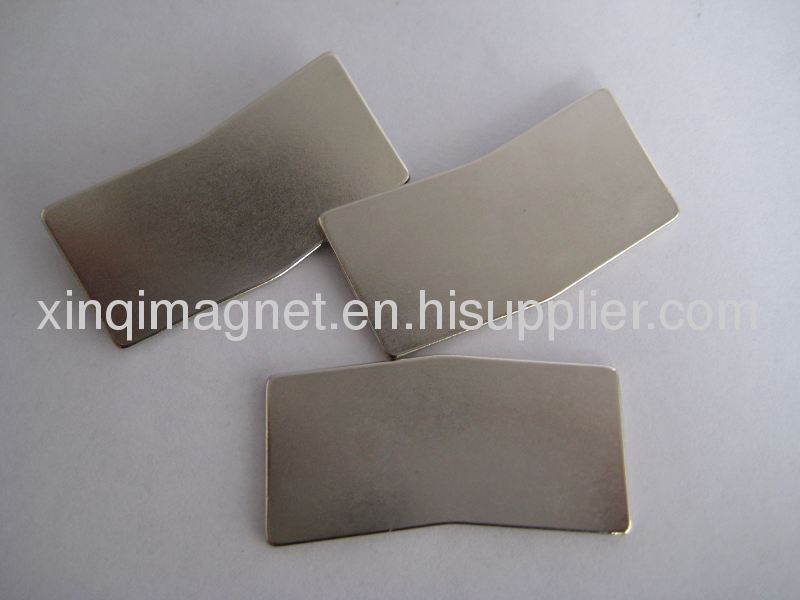

product name :Permanent NdFeB irregular shape, used in motor

The main raw material of the NdFeB permanent magnets are the rare earth metal neodymium (Nd) 32%, the metal elements iron (Fe) 64% and non-metallic elements boron (B) 1% , adding a small amount of dysprosium (Dy), terbium (Tb), cobalt(Co), Niobium (Nb), gallium (Ga), aluminum (Al), copper (Cu) and the like elements. NdFeB ternary compounds is based on the Nd2Fe14B, its composition should be similar with Nd2Fe14B Formula.

It is have three main parameters: First, Br (Residual Induction), GAUSS of units, which is the residual magnetic flux density when the magnetic field is removed from saturation, representing the external magnetic field strength which it can provide; Second, Hc (Coercive Force), Oersteds of units, Putting the magnet on a reverse magnetic field, its properties will disappear when the applied magnetic field is increased to a certain intensity, the ability to resist the applied magnetic field is known as the coercive force, represents the ability to measure the resistance to demagnetization; Third, BHmax, Gauss-Oersteds of units, which is the magnetic energy from the unit volume of material, it is a physical quantity.

Product picture:

Features:

1) Irregular block NdFeB magnets used in motor

2) Size:60*25*2mm

3) Grade: 40SH

4) Coating: Nickle(≥15um)

5) Magnetized through thickness

6)Excellent demagnetization resistance capability.

7)ISO/TS16949 passed

Packing:

Inner packing: small white box, place plastic between each magnet

Outer packing: Carton outside, small white box with OPP bag inside

Other physical properties of Nd-Fe-B:

Br temperature coefficient: -0.11%/°C

Density: 7.4g/cm3

Webster's temperature: 600Hv

Tensile heat-distortion: 8.0kg/mm2

Specific heat: 0.12k Cak(kg°C)

Modulus of elasticity: 1.6x1011N/m2

Poisson ratio: 0.24

Curie temperature: 310-340°C

Resistivity: 144Ω.cm

Flexural strength: 25kg/mm2

Coefficient of thermal expansion: 4x10-6/°C

Thermal conductivity: 7.7cal/m.h.°C

Stiffness: 0.64N/m2

Compression ratio: 9.8x10-12m2/N

iHc temperature coefficient: -0.60%/°C

Properties:

| Sintered Nd FeB magnetic properties | |||||||||

| (Hcb) | (Hcj) | (BH)max | Max Working | ||||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | Tempt(TW)℃ |

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| N40 | 1250-1280 | 12.5-12.8 | ≥907 | ≥11.4 | 302-326 | 38-41 | |||

| N42 | 1280-1320 | 12.8-13.2 | ≥915 | ≥11.5 | 318-342 | 40-43 | |||

| N45 | 1320-1380 | 13.2-13.8 | ≥923 | ≥11.6 | 342-366 | 43-46 | |||

| N48 | 1380-1420 | 13.8-14.2 | 366-390 | 46-49 | |||||

| N50 | 1400-1450 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 | |

| N52 | 1430-1480 | 14.3-14.8 | 398-422 | 50-53 | |||||

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42M | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45M | 1320-1380 | 13.2-13.8 | ≥12.5 | 342-366 | 43-46 | ||||

| 48M | 1370-1430 | 13.7-14.3 | ≥1027 | ≥12.9 | 366-390 | 46-49 | |||

| 50M | 1400-1450 | 14.0-14.5 | ≥1033 | ≥13.0 | 382-406 | 48-51 | |||

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45H | 1320-1360 | 13.2-13.6 | ≥963 | ≥12.1 | 326-358 | 41-46 | |||

| 48H | 1370-1430 | 13.7-14.3 | ≥995 | ≥12.5 | 366-390 | 46-49 | |||

| 35SH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2=12.5 | ≥907 | ≥11.4 | 287-310 | 36-39 | |||

| 40SH | 1250-1280 | 12.5=12.8 | ≥939 | ≥11.8 | 302-326 | 38-41 | |||

| 42SH | 1280-1320 | 12.8=13.2 | ≥987 | ≥12.4 | 318-342 | 40-43 | |||

| 45SH | 1320-1380 | 13.2=13.8 | ≥1003 | ≥12.6 | 342-366 | 43-46 | |||

| 28UH | 1040-1080 | 10.4=10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | 180℃ |

| 30UH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33UH | 1130-1170 | 11.3=11.7 | ≥852 | ≥10.7 | 247-271 | 31-34 | |||

| 35UH | 1170-1220 | 11.7=12.2 | ≥860 | ≥10.8 | 263-287 | 33-36 | |||

| 38UH | 1220-1250 | 12.2=12.5 | ≥876 | ≥11.0 | 287-310 | 36-39 | |||

| 40UH | 1250-1280 | 12.5=12.8 | ≥899 | ≥11.3 | 302-326 | 38-41 | |||

| 28EH | 1040-1080 | 10.4=10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | 200℃ |

| 30EH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33EH | 1130-1170 | 11.3=11.7 | ≥876 | ≥11.0 | 247-271 | 31-34 | |||

| 35EH | 1170-1220 | 11.7=12.2 | ≥11.0 | 263-287 | 33-36 | ||||

| 38EH | 1220-1250 | 12.2=12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 28AH | 1040-1080 | 10.4=10.8 | ≥787 | ≥9.9 | ≥2624 | ≥33 | 207-231 | 26-29 | 230℃ |

| 30AH | 1080-1130 | 10.8=11.3 | ≥819 | ≥10.3 | 223-247 | 28-31 | |||

| 33AH | 1130-1170 | 11.3=11.7 | ≥843 | ≥10.6 | 247-271 | 31-34 | |||

Representive products:

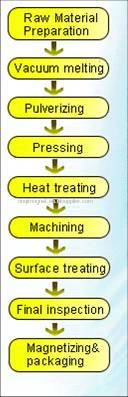

Production process: