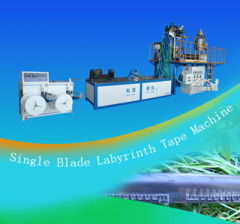

Single blade labyrinth type drip irrigation tape making machine

40000.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Hebei |

Company Profile

| Location: | Tangshan, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Drip Irrigation Tape Making Machine |

Product Detail

| Model No.: | SJDYG-60 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Brand Name: | ZFSJ |

| production speed: | 65-70m/min |

| Packing: | Wooden box |

Product Description

Characteristics of the machine

1. The production line adopts PLC central control, man-interface operation, with high production speed, stable working condition and high automation.

2. The extruder, shaping device, and tractor all adopt frequency conversion control, which works more saves energy consumption.

3. The heating system of extruder and extrusion mold adopt temperature control module, the accuracy of controlling the temperature is high, which makes the materials plasticized well and the tape surface even.

4. The diameter of tape if controled by automatic diameter gauge, the measurement and control of tape is accurate, steady and reliable.

5. The cooling device is strong, making the drip irrigation tape cooling and sizing rapidly, thus increasing the production speed.

6. The machine adopts three-station rolling method, which reduce the labor intensity. The drip irrigation tape is curled by moment electrical machinery. The drip irrigation tape can overcome the tension emerged effectively. The machine still has the equipment to calculate the length of the drip irriagtion tape. The rolling length can be settled casually below 2500m(if meter prolonging isrequired, it can be ordered). The rolling machine has the functions of memory and automatic alarming etc.

7. The whole machine is designed compactly, reasonably, beautifully.

Features of the drip irrigation tape

1. The labyrinth flow passage, water dripping outlet and pipeline can be formed once, which performance is good.

2. The labyrinth water flow passage is much wider, the water flow state is turbulent and it has many water entrances which can prevent tape from clogging strongly.

3. Multi water outlets greatly lowers the risk of water interception due to the outside blocking.

4. It can be widely applied to greenhouse and farm land paved along crops, the dripping volume and space of dripping outlet can be supplied according to actual needs.

1. The production line adopts PLC central control, man-interface operation, with high production speed, stable working condition and high automation.

2. The extruder, shaping device, and tractor all adopt frequency conversion control, which works more saves energy consumption.

3. The heating system of extruder and extrusion mold adopt temperature control module, the accuracy of controlling the temperature is high, which makes the materials plasticized well and the tape surface even.

4. The diameter of tape if controled by automatic diameter gauge, the measurement and control of tape is accurate, steady and reliable.

5. The cooling device is strong, making the drip irrigation tape cooling and sizing rapidly, thus increasing the production speed.

6. The machine adopts three-station rolling method, which reduce the labor intensity. The drip irrigation tape is curled by moment electrical machinery. The drip irrigation tape can overcome the tension emerged effectively. The machine still has the equipment to calculate the length of the drip irriagtion tape. The rolling length can be settled casually below 2500m(if meter prolonging isrequired, it can be ordered). The rolling machine has the functions of memory and automatic alarming etc.

7. The whole machine is designed compactly, reasonably, beautifully.

Features of the drip irrigation tape

1. The labyrinth flow passage, water dripping outlet and pipeline can be formed once, which performance is good.

2. The labyrinth water flow passage is much wider, the water flow state is turbulent and it has many water entrances which can prevent tape from clogging strongly.

3. Multi water outlets greatly lowers the risk of water interception due to the outside blocking.

4. It can be widely applied to greenhouse and farm land paved along crops, the dripping volume and space of dripping outlet can be supplied according to actual needs.

Details

Production speed:65-70m/min

Main driving power:18.5kw

Filter changing method:Durable filter(patent)

Installation power:44kw

Water consumption:1m3/h

Air consumption:0.3m3/h

Weight:2200kg

Max.extruding capacity:55kg/h

Production speed:65-70m/min

Main driving power:18.5kw

Filter changing method:Durable filter(patent)

Installation power:44kw

Water consumption:1m3/h

Air consumption:0.3m3/h

Weight:2200kg

Max.extruding capacity:55kg/h

.jpg)