Double plate double working position hydraulic screen changer

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Double plate double working position hydraulic screen changer

Double plate double working position hydraulic screen changer

This kind of screen changer is better than the single plate screen changer, there are two flow channels, so when we replace the dirty screen, the melt folw will not be interrupted.

It contains two screens that work at the same time: one screen works, while the other one is changed during the process of screen replacements, thus the replacement without machine halt is ensured and no interrupt of material fluid and of production will occur. Therefore, the screen changer meets the customers' requirement of higher productivity and better quality.

1,Automatic screen changing by hydraulic; Machine non-stopped\

2,Special sealed structure design(self-owned patent),excellent effect, no material leakage for more than five years.

3, Simple construction, reliable operation; Easy maintenance, lower running cost;

4, Flow channel without the dead spots, it's easy to clean and maintain the machine.

How to work

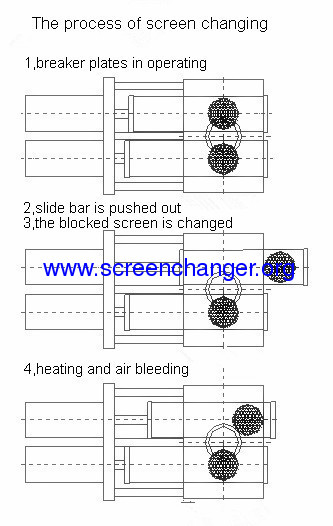

The double piston Screen Changer allows for filtration of most all polymers without interrupting production during a screen change. The Screen Changer consists of two pistons with each containing a filter cavity. When a screen change is required, one of the pistons is moved out of the housing while the other remains in the operating position. The dirty screen pack is removed and replaced with a new one. The piston is then moved back into the housing to its venting stages before resuming operation. These steps are then repeated for the other piston. This concept allows for continuous filtration with no interruption or loss of production

Application fields:

1. Used for the production of plate, sheet, cast film, pipe, granulation and so on.

2. Applicable to the production line of colossal, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture, filtering screen replacement available without machine halt.

Commissioning

At the requirement of customer, seller should send technicians to install and debug the screen changer to the die at site of Buyers, Travelling expenses and accommodation fee should be borne by Buyers.

Warranty

"three guarantees"(return, replacement, repair) of all the spare parts for one year. Travelling expenses and accommodation fee for"three guarantees" will be borne by users.

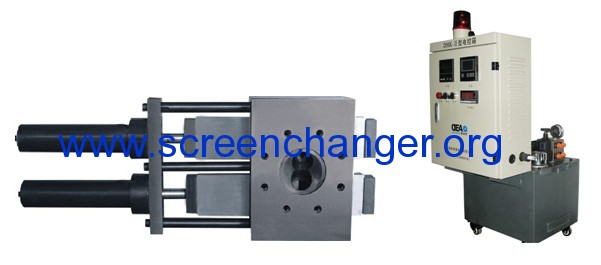

The body of the double plate double working position hydraulic screen changer

The application showing cases