Double piston double working position screen changer/melt filter DHZ-2-600

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHZ-2-600 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 350bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Double piston double working position screen changer/melt filter DHZ-2-600

This double piston screen changer is made up of

1,the body of the screen changer

2,the cyclinder

3,the heater

4 ,the hydraulic unit

5,the electric controlling cabinet and the breaker plate.(pressure sensor, pressure meter, temperature meter, warning device are included)

Features of this type of screen changer

1,This model double piston double working position screen changer/melt filter DHZ-2-600

the filter screen is oval , not round, thus increase the filter screen area, to meet the high yield device- high output extruder.

2, the electrical controlling cabinet is optional, not the standerd configuration. But equiped with the electrial controlling cabinet , we can know clearly the time to replace the screen , for example, we preset the screen changer pressure is 15Mpa, when the polmer melt pressure is up to 15Mpa, the warning device will alarm automatically , then it's time for us to replace the screen.

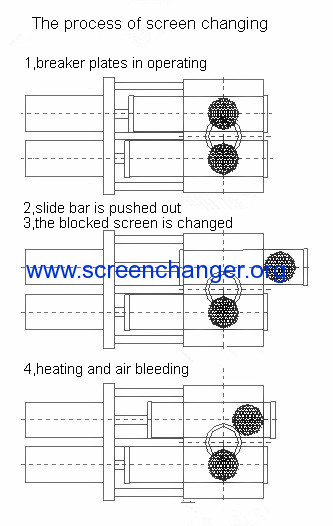

3, this knd of screen changer is a continuous type, no disturb the production when change the screen. we do not replace thetwo dirty screen in the same time, but one after the other, thus the polymer melt flow will not be interrupted.

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers