Plate type hydraulic melt filter for plastic extruder

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

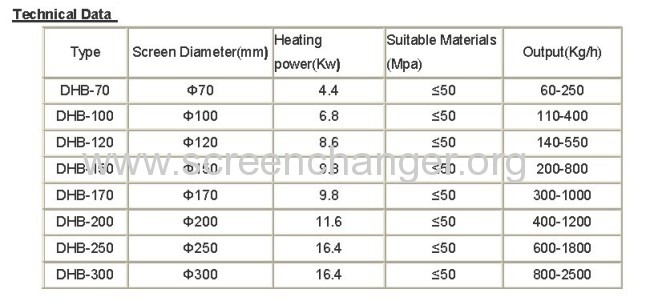

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Purification Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Plate type hydraulic melt filter for plastic extruder

plate type hydraulic screen changer

single plate screen changer

This kind of screen changer DHB series is the most widely used in all over the world , and it's known for the low price ,proven technique and easy operation.

The structure of the plate type hydraulic melt filter for plastic extruder

1, the body of the screen changer, consists of the main body and the slide plate

2, the hydraulic unit with accumlator, it's the power of fast screen change.

3, the electric controlling pack. pressure sensor, warning device, temperature and pressure meter are included

4,breaker plate, each sets of screen changer owns two or more pieces of breaker plate

The following picture shows the main parts of this kind of screen changer

Do you want to know why this kind of plate type hydraulic melt filter is so popular? what kinds of advantages does it have?

1, this kind of screen changer is very flexible. we can install it any direction you like, horizontally, slantly, or vertically. And it's performance will not be impacted. it's real a good news for somewhere the space available is restricted.

2, several sets of this kind of plate type hydraulic melt filter can be controlled by one set hydraulic unit. For maximum use of space, and economic advantage, so this kind of screen changer now is welcome by the co-extrusion/multi-layer extrusion line.

3, The block of the accumulator prevents the hydraulic unit to exceed the adjusted maximum pressure, so it's safe to operate.

4, the short screen change time. to replace the dirty screen by a new one, only need less than 2 seconds, and it's not by manual, but the strong power provided by the accmlator .

Applications

.Corrugated pipe production line

.co-extrusion single screw extruder

.granulation line

Such as

.PC.PMMA.PS.MS sheet production line

.PP.HIPS.PE.EVA.EVAOH single screw multi-layers composite sheet production line

PP.PE board production line

.PMMA transparent sheet production line

.PC.PP hollow profile board production line

.ABS single layer ,multi-layers composite sheet production line

.ABS.PP.PS anti-static co-extrusion sheet production line

.Wide floor sheet, water proof sheet production line

More pictures of this kind of plate type hydraulic melt filter for plastic extruder