Plastic extruder continuous screen changer double chanel type

1.0~40000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

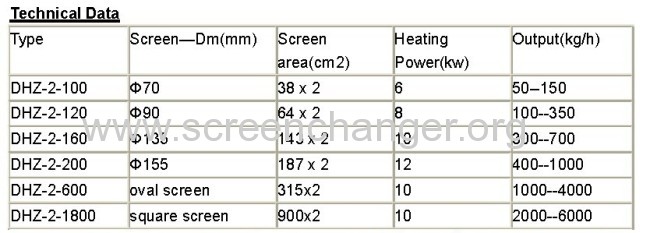

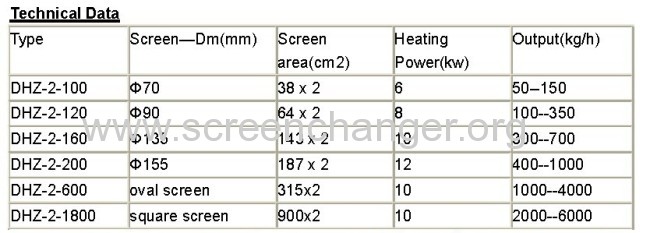

| Model No.: | DHZ |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 350bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Plastic extruder continuous screen changer double chanel type

This kind of DHZ series screen changer we also called it

double piston screen changer

double pillar screen changer

double column screen changer

two chanel screen changer

A picture of the plastic extruder continuous screen changer double chanel type.

its structure just like its name, there are two pistons on the screen changer body, and each piston there is a screen, round or oval, we do this to increase the screen area . how does the plastic extruder continuous screen changer double chanel type, in the normal time, the two screens are on the working position , when the screen change is required , one of the piston with the dirty screen will be pushed out , and we replce the screen with a new one, then the piston is pushed into the working position. and the next step is to chage the other screen on the other piston.

Which kind of products fit for this continuous screen changer double piston type?

This kind of DHZ series screen changer we also called it

double piston screen changer

double pillar screen changer

double column screen changer

two chanel screen changer

A picture of the plastic extruder continuous screen changer double chanel type.

its structure just like its name, there are two pistons on the screen changer body, and each piston there is a screen, round or oval, we do this to increase the screen area . how does the plastic extruder continuous screen changer double chanel type, in the normal time, the two screens are on the working position , when the screen change is required , one of the piston with the dirty screen will be pushed out , and we replce the screen with a new one, then the piston is pushed into the working position. and the next step is to chage the other screen on the other piston.

Which kind of products fit for this continuous screen changer double piston type?

1, used for the pipe, sheet ,cast film, granulation and so on

2. Applicable to the production line of colossal, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture, filtering screen replacement available without machine halt.

How long time do we need to change the screen?

it's depends on the contaminate degree of the raw material, if the material is very dirty, the screen change interval will be short.

Do we must need the electrical controlling pack?

it's not a must, but if we install the electrical controlling pack, there is a warning device, when the screen change is required, the warning device will alarm automatically. it is easy for us to operation.

The following are some pictures of the plastic extruder continuous screen changer double piston type.

How long time do we need to change the screen?

it's depends on the contaminate degree of the raw material, if the material is very dirty, the screen change interval will be short.

Do we must need the electrical controlling pack?

it's not a must, but if we install the electrical controlling pack, there is a warning device, when the screen change is required, the warning device will alarm automatically. it is easy for us to operation.

The following are some pictures of the plastic extruder continuous screen changer double piston type.