continuous hydraulic filter-screen changer

1.0~7000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHBL |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

continuous hydraulic filter-screen changer

new continuous screen changer

hydraulic plate screen changer- continuous type

Features of this series of screen changer

1, continuous type, means no need to stop the on-going machine when change the screen

2, no interrupt the polymer material flow, so no disturb the prodution

3, exhaust system, improve the quality of the products

4, this kind of screen changer is widely used in th XPS/EPS/EPE foaming products.

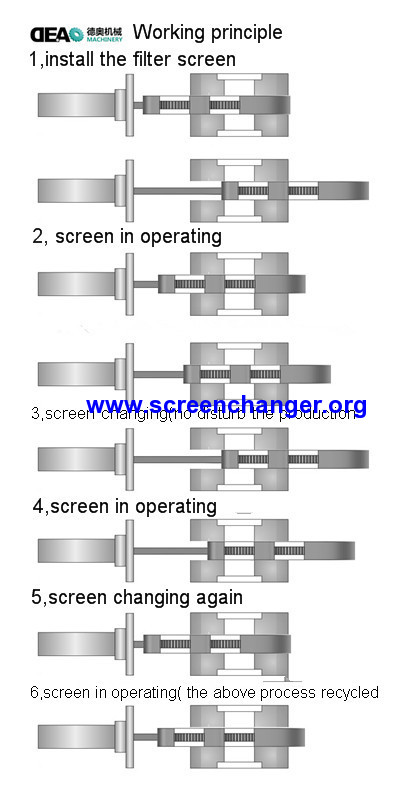

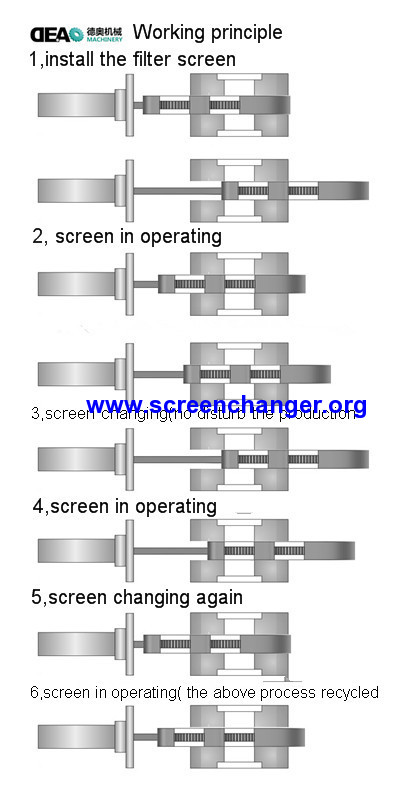

The working principle of this kind of screen changer

The pictures of the screen changer

new continuous screen changer

hydraulic plate screen changer- continuous type

Features of this series of screen changer

1, continuous type, means no need to stop the on-going machine when change the screen

2, no interrupt the polymer material flow, so no disturb the prodution

3, exhaust system, improve the quality of the products

4, this kind of screen changer is widely used in th XPS/EPS/EPE foaming products.

The working principle of this kind of screen changer

Type | Screen type (mm) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHBL-80 | 70×70 | 3 | ≤50 | ≤250 |

DHBL-100 | 100×90 | 5.6 | ≤50 | ≤450 |

DHBL-130 | 120×110 | 6.8 | ≤40 | ≤550 |

DHBL-150 | 140×130 | 8 | ≤40 | ≤900 |

DHBL-200 | 190×170 | 10 | ≤30 | ≤1500 |

The pictures of the screen changer