Belt filter- automatic continuous screen changer

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Belt Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Auto belt screen changer for extrusion lines

Automatic uninterrupted continuous polymer filtration

The automatic belt screen changer is a compact, self-contained screen changer that eliminates the need for hydraulics, screen packs, breaker plate cleaning or replacement, with no electric motors or hydraulics.

Features

•Continuous production with automatic and constant screen changing process, no manual operation.

•Minimized material flow and pressure fluctuation during whole production process, excellent product stability.

•Reducing waste and raw materials consumption.

Benefits

•It guarantees continuous production, and requires no operator assistance while running.

•Higher Product Quality

•It has no motor or moving mechanical parts. It requires minimum maintenance interventions, continuous production achievable evening during belt screen replacement.

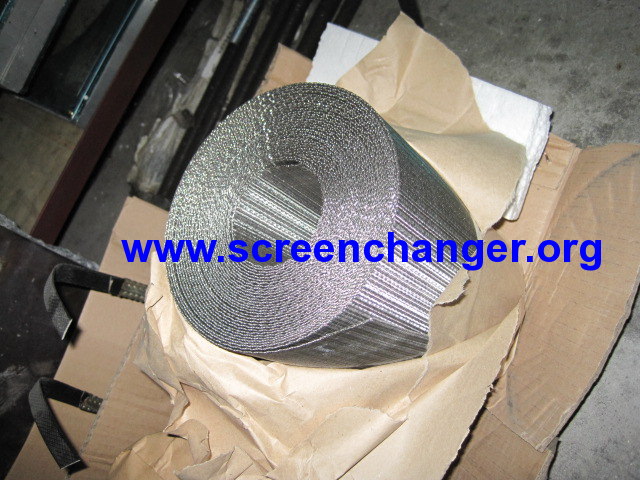

The screen belt

The whole set of Auto belt screen changer for plastic extrusion lines