automatic screen changer for plastic machinery

1.0~10000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DEAO |

| Belong to: | spare parts of plastic extrusion machine |

| Function: | polymer melt filtration |

| suitable materials: | almost all polymers PP/PE//ABS/XPS/WPC |

| Application: | pipe/sheet/plate/tube/compounding/blow film/cast film/fiber and so on |

| Type: | different types to be match with extruders |

| high pressure resistant: | 500bar |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40days after receiving down payment |

Product Description

Automatic screen changer for plastic machinery

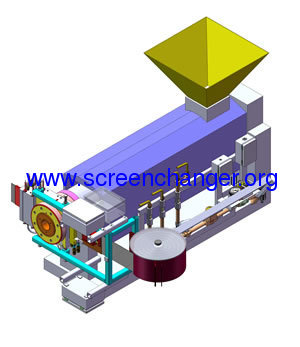

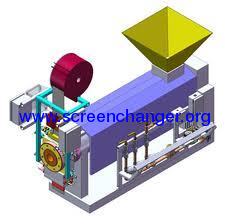

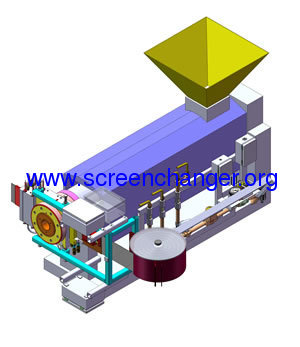

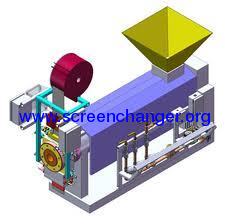

Automatic belt screen changer for plastic extrusion machine

Automatic belt screen changer for plastic extrusion machine

The automatic belt screen changer is a compact, self-contained screen changer that eliminates the need for hydraulics, screen packs, breaker plate cleaning or replacement, with no electric motors or hydraulics.

Features of Automatic screen changer for plastic machinery

Features of Automatic screen changer for plastic machinery

•Continuous production with automatic and constant screen changing process, no manual operation.

•Minimized material flow and pressure fluctuation during whole production process, excellent product stability.

•Reducing waste and raw materials consumption.

Benefits of Automatic screen changer for plastic machinery

•It guarantees continuous production, and requires no operator assistance while running.

•Higher Product Quality

•It has no motor or moving mechanical parts. It requires minimum maintenance interventions, continuous production achievable evening during belt screen replacement.

The automatic screen changer can be horizontal installation and vertical installation.

How to work

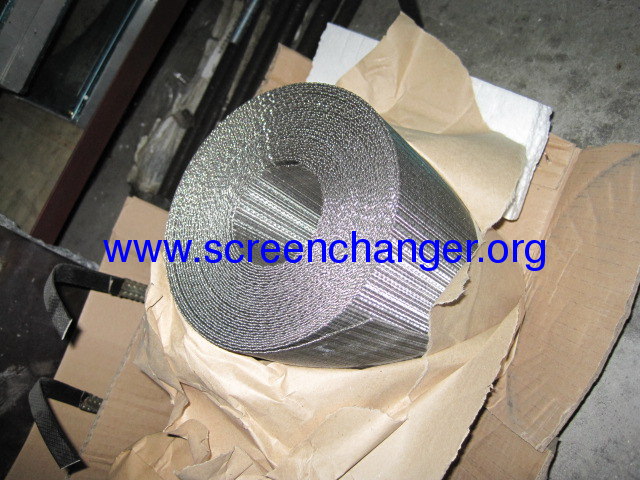

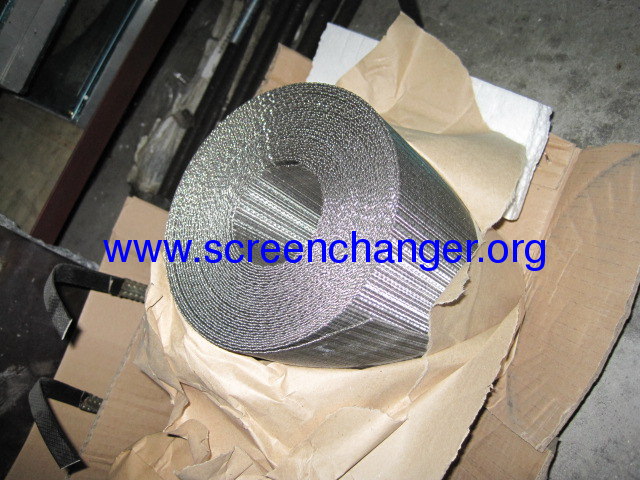

The screen moves across the flow of plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |

The automatic screen changer can be horizontal installation and vertical installation.

.jpg)