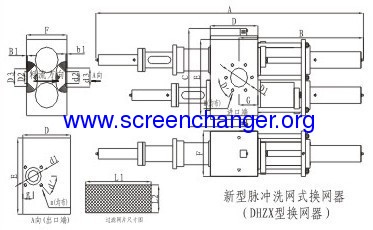

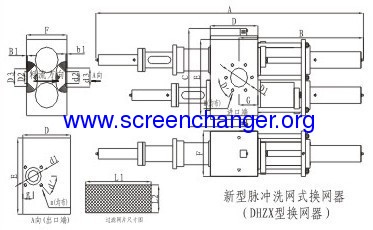

New pulse-washing screen changer

1.0~7000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHZX |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 500bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

New pulse-washing screen changer

New pulse backflush screen changer

New pulse backflush screen changer

The new high-pressure pulse backflush screen changer is the latest product developed by Deao of self-owned Chinese invention patent and international invention patent. There is no need to change the screen, but backflush of rapid pulse by little clean material in the machine. It is a symbol of internationally advanced technology, and is especially applicable for the machines of waste recycling and granulating, and direct waste processing. It is applied in the process of medium and large production lines with the features of high precision filtration, large production flow, good stability, and high automation.

Performance Characteristics:

The Back-flush screen changer from our company is similar with the double piston screen changer,and it adds a back-flush cylinder which is connected with the double piston. screen washing on line available(A small amount of clean material flows in reverse under high pressure, rinse the dirty screen

How to work

The Back-flush screen changer from our company is similar with the double piston screen changer, and it adds a back-flush cylinder which is connected with the double piston. Screen washing on line available (A small amount of clean material flows in reverse under high pressure, rinse the dirty screen

Application fields:

1. Applicable to all the kinds of plastic products. specially in the recycling and granulation combined with high impurities, such as PE/PP/PS/ABS/PET/PA/etc.

2. Applicable to the production line of chemical fiber, rubber, collosol, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture.

3. It has been applied in the United States PS recycling machine. Its output is 1100kg/hr, filtration precision of 40-60 mesh, new screen pressure of 2.5Mpa, material pressure of 7.5Mpa after admixture. The material pressure reduced to 2.5 -2.7Mpa after strongly washing the filter, filter cleaning rate exceeds 90%.

Commissioning

At the requirement of customer, seller should send technicians to install and debug the screen changer to the die at site of Buyers, Travelling expenses and accommodation fee should be borne by Buyers.

Warranty

"three guarantees"(return, replacement, repair) of all the spare parts for one year. Travelling expenses and accommodation fee for"three guarantees" will be borne by users.

Screen size L×W (cm) | Screen area(cm2) | Pressure (Mpa) | Heating Power(kw) | Output(kg/h) | |

DHZX-120 | 193×2 | ≤25 | 14 | ≤2000 | |

DHZX-160 | 423×2 | ≤25 | 14 | ≤2500 | |

DHZX-1800 | 47×19 | 900×2 | ≤25 | 14 | ≤3000 |

DHZX-2000 | 47×21 | 1000×2 | ≤25 | 14 | ≤4000 |

DHZX-2250 | 53×21 | 1125×2 | ≤25 | 14 | ≤4500 |

DHZX-2700 | 53×25 | 1335×2 | ≤25 | 14 | ≤5400 |

DHZX-3300 | 66×25 | 1650×2 | ≤20 | 20 | ≤6600 |

DHZX-4400 | 88×25 | 2200×2 | ≤20 | 20 | ≤8400 |

DHZX-5650 | 94×30 | 2827×2 | ≤20 | 20 | ≤11300 |