China screen changer-non stop plate screen changer

1.0~40000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 50 pieces per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Belong to: | parts and components for plastic extruders |

|---|---|

| Function: | plastic melt filtration system |

| Use for: | the production of plastic |

| Suitable materials: | almost all polymers PP/PE//ABS/XPS/WPC |

| designed to match with different size of extruder: | agent wanted |

| Production Capacity: | 50 pieces per month |

| Packing: | seaworthy packing |

| Delivery Date: | within 50 days after PO conformation |

Product Description

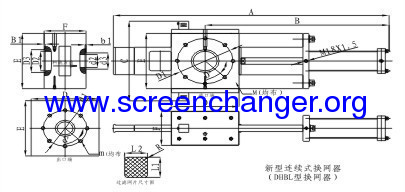

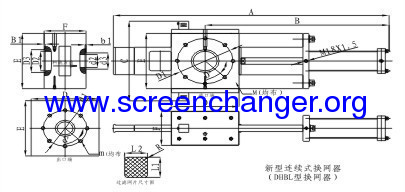

China screen changer-non stop plate screen changer

Features of DHB series of screen changer

This DHB series of screen changer consists of main body, slide plate, heater and hydraulic unit with accumulator. It is driven by hydraulic power, and the slide plate carries 2 pieces breaker plates can move linearly in both directions to achieve screen changing in a short time.

Features of DHB series of screen changer

Deao patented technology on the sealing system design. Automatic compensation on sealing gap can be realized during screen changing process. Compatible with extruders for various polymers processing at high output.

Filtration screen diameter ranges from 70-360mm

How to work

The plate has two screen cavities ,one of them work with the plastic machine at the same time, when a screen change is required, the cavity with dirty screen will be moved out by hydraulic in a minimum time, and at the same time, the other cavity with new screen will be moved into the working position . the screen replacement is very short and no need shut down the working machine

Application fields:

1,Applicable to the production of various thermoplastic, chemical fiber, rubber, colossal, adhesive, coating and finishing materials alike, mainly used for filtration of the material mixture.

2,Such as blow-molding machines, film blowing machines, GRP processing machinery, granulators, Styrofoam machines, extrusion machines, plastic product making machines

After-sales service

6 months with proper operation by user, all the spare parts shall be replaced free of charge under guarantee period, fee for transportation and packing will be borne by users.

Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) | |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Our advantages

We are specialized in the research and manufacturing of melt filtration device/screen changer for more than 20 years. With strong scientific research team and mature technology; hold many international and national invention patents.

Our items can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and quality much better, energy-saving and consumption-reducing, output- increasing and labor-saving