DHB series single plate hydraulic screen changer

1.0~7000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Land |

| Belong to: | Auxiliary parts of plastic extrusoin plant |

| Function: | melt filter/screen changer for extruder |

| fit for: | almost all polymers PP/PE//ABS/XPS/WPC |

| Application: | film blowing pipe making, plate making and granulating and so on |

| different type: | different types to be match with extruders |

| material: | alloy steel |

| pressure resistant: | 50Mpa |

| Heating power: | 2.2kw |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

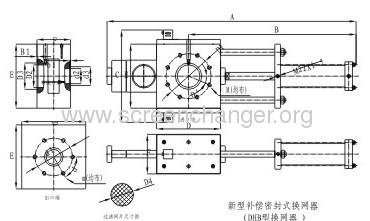

DHB series single plate hydraulic screen changer

Features of the DHB series single plate hydraulic screen changer

1) quick

To move from the filtering screen in use to the clean screen takes only a minimum time, less than 2 seconds

•Extraction and replacement of the filtering screens take place very quickly and maintenance can be carried out in a short time

•The speed of the change from one screen to the other means that the action of the extruder is not interrupted

2)flexible

Single plate screen changer can be mounted both horizontally and vertically without affecting performance; in addition the single plate screen changer can be controlled by just one hydraulic unit.

•Mounted both horizontally and vertically, the single plate screen changer can be introduced very successfully onto pre-existing installations or where the space available is restricted, but without compromising high quality processing

•Several single plate screen changers can be controlled by the same hydraulic unit, resulting in large savings and maximum use of space3)safe

The screen changer is provided with several devices which guarantee its safe use.

•The safety blocking system of the doors and the hydraulic unit protects from the movements of the plates and from accidental opening during maintenance

•The block of the accumulator prevents the hydraulic unit to exceed the adjusted maximum pressure

• guarantee a perfect seal during the sliding of the plates

Special installations

The DHB SERIES can be installed both horizontally and vertically and can be introduced into pre-existing installations or where the space available is restricted but without compromising high quality processing.

For maximum use of space, and economic advantage, several DHB series screen changers can be connected to one hydraulic unit.

Applications

Blown film and cast film (Bubble pack/ Medical/Food Wrap)

Coating (Hot melt adhesive)

Compounding (Master batch/filler)

Wire and cable extrusion

Tubing (Medical/Industrial/Irrigation)

Fibers ( Monofilament)

Pelletizing (strands and underwater)

Recycling of most polymers

Technical Data

Type | Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |