hydraulic screen changer for extrusion plant

1.0~50000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 pieces per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| material: | high quality alloy steel |

| used for: | plastic melt filtration |

| fit for: | almost all polymers PP/PE//ABS/XPS/WPC |

| type: | various kinds designed to be match with all kinds of extruder |

| Production Capacity: | 50 pieces per month |

| Packing: | seaworthy packing |

| Delivery Date: | 30days after receiving down payment |

Product Description

The new sealed compensation screen changer, or as is called, the plate screen changer, is widely used for the production of various plastics.

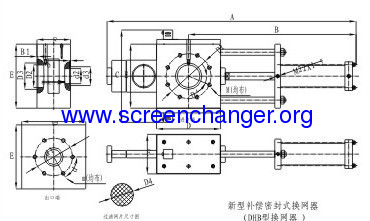

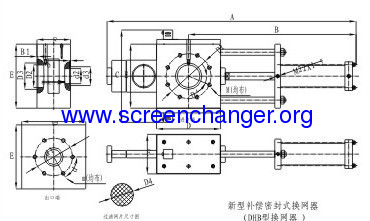

New sealed compensation screen changer

Performance characteristics:

Application fields:

The new sealed compensation screen changer, or as is called, the plate screen changer, is widely used for the production of various plastics and chemical fibers. It is of high performance/price ratio, and ensures the screen changing without machine halt, or any material leakage under high pressure. Therefore, it is especially applicable to large scale machines of film blowing, pipe making, plate making and granulating, etc.

Performance characteristics:

1\Automatically compensates the sealed surface clearance(self-owned patent), high-pressure resistant, high-temperature resistant, and no material leakage. Contain screens of large filtering area, especially appropriate for high yield production line under high pressure.

2\No need to stop the working machine when changing the screen, easy to operate and maintain, reliable for higher production output and lower energy consumption, 80%-90% down of waste material caused by screen changing.

Application fields:

Applicable to the production of various thermoplastic, chemical fiber, rubber, collosols, adhesive, coating and finishing materials alike, mainly used for filtration of the material mixture.

Technical Data

Type | Screen—Dm(mm) | Heating Power(kw) | Pressure(Mpa) | Output(Kg/h) |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ165 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |