hydraulic screen changer for twin-screw extruder

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 20-50sets/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

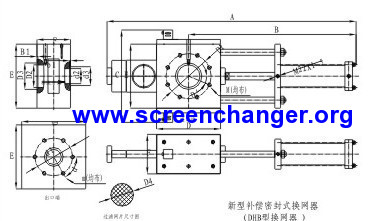

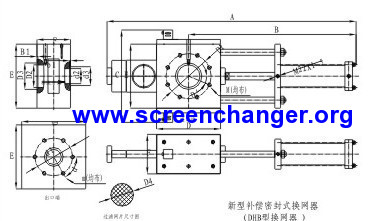

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Filtering Machine |

| Brand Name: | DEAO |

| china made screen changer: | autoscreen changer for machines |

| Function: | filtration of the plastic melt |

| material: | high quality alloy steel |

| components of extrusion machine: | agents and distributor will be welcome |

| pressure resistant: | 50Mpa |

| designed to match with different size of extruder: | various type |

| Production Capacity: | 20-50sets/month |

| Packing: | stanadard seaworthy packing |

| Delivery Date: | 40days after receiving down payment |

Product Description

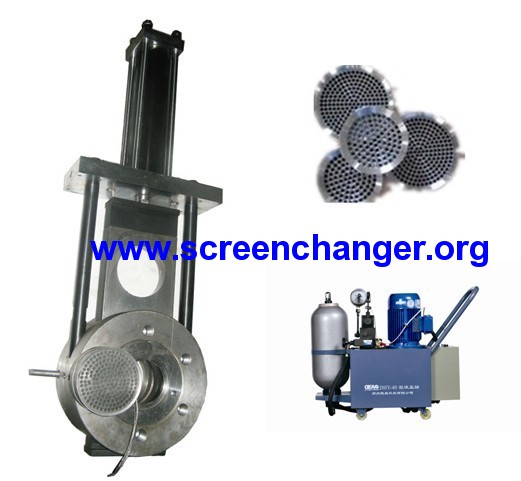

hydraulic screen changer for twin-screw extruder

single plate screen changer

discontinuous screen changer

Technical Data of the hydraulic screen changer for twin-screw extruder

single plate screen changer

discontinuous screen changer

Technical Data of the hydraulic screen changer for twin-screw extruder

Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) | |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Specification of hydraulic screen changer for twin-screw extruder

1, Automatically compensates the sealed surface clearance (self-owned patent)

2, No need to stop the working machine when changing the screen

3, Excellent quality and reasonable price

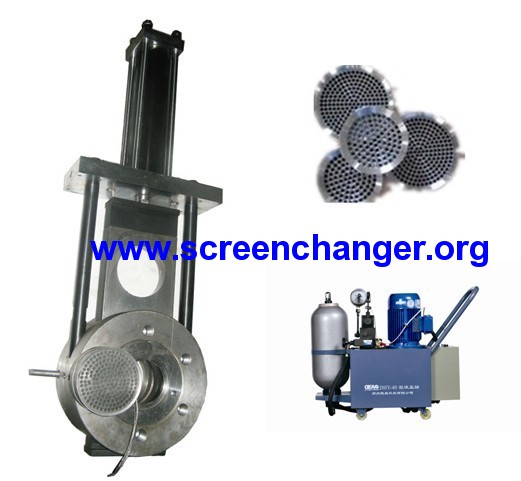

How to work

hydraulic screen changer for twin-screw extruder

The plate has two screen cavities ,one of them work with the plastic machine at the same time, when a screen change is required, the cavity with dirty screen will be moved out by hydraulic in a minimum time, and at the same time, the other cavity with new screen will be moved into the working position . the screen replacement is very short and no need shut down the working machine

The plate has two screen cavities ,one of them work with the plastic machine at the same time, when a screen change is required, the cavity with dirty screen will be moved out by hydraulic in a minimum time, and at the same time, the other cavity with new screen will be moved into the working position . the screen replacement is very short and no need shut down the working machine

Application fields:

1,Applicable to the production of various thermoplastic, chemical fiber, rubber, colossal, adhesive, coating and finishing materials alike, mainly used for filtration of the material mixture.

2,Such as blow-molding machines, film blowing machines, GRP processing machinery, granulators, Styrofoam machines, extrusion machines, plastic product making machines

.jpg)