Automatical belt screen changer

1.0~40000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 pieces per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | Auto belt screen changer |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Deao |

| Belong to: | parts and components for plastic extruders |

| Function: | filter |

| Use for: | melt filter/screen changer for extruder |

| Suitable materials: | almost all polymers PP/PE//ABS/XPS/WPC |

| Production Capacity: | 50 pieces per month |

| Packing: | standerd wooden case |

| Delivery Date: | within 50 days after PO conformation |

Product Description

without manual operation

2,no fluctuation of material flow

3, automatic screen replacing by pressure differential of the plastic melt.

Automatic belt screen changer

The automatic mesh belt screen changer is mainly composed of the screen changer, the heating and cooling system, and the electric control system. There is no need of manual operation of the screen changer because the material fluid inside flows by itself under the pressure caused by the melt production.

How to work

Automatical belt screen changerThe screen moves across the flow of plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

Features of Automatical belt screen changer

1. Automatically and continuous screen replacement without manual operation.

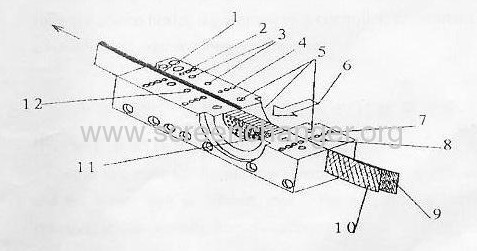

(1)Moving screen mesh heater;

(2)Adiabatic isolation hole

(2)Adiabatic isolation hole

(3)Export cooling area water holes

(4)Adiabatic isolation hole

(5)Filtering district heating holes

(6)Flow direction

(7)inlet heat insulation hole

(8)outlet cooling water area

(9)Fine mesh belt

(10)Support mesh(coarse screen)

(11)Support of the porous plate mesh

(12)outlet of cooling water holes

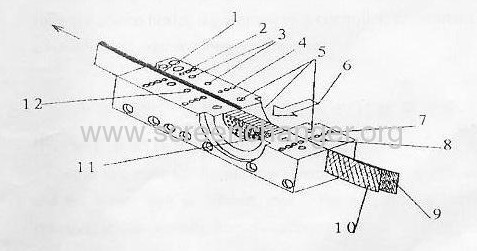

(4)Adiabatic isolation hole

(5)Filtering district heating holes

(6)Flow direction

(7)inlet heat insulation hole

(8)outlet cooling water area

(9)Fine mesh belt

(10)Support mesh(coarse screen)

(11)Support of the porous plate mesh

(12)outlet of cooling water holes

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |

How to work

Automatical belt screen changerThe screen moves across the flow of plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

Features of Automatical belt screen changer

1. Automatically and continuous screen replacement without manual operation.

2. No fluctuation of material flow, no product deformation, excellent quality stability.

3. No waste product or waste material, and little material consumption occur when the screen changer works.

4. Simple construction, reliable operation; Easy maintenance, lower running cost;

Automatic screen replacing by pressure differential of the plastic melt; Machine will not be stopped as the screen replacing.