Automatic mesh belt screen changer- use for cast film extrusion

1.0~15000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 pieces/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| raw material: | high quality alloy steel |

| Application: | almost all kinds of polymers |

| Belong to: | Auxiliary parts of extrusoin plant |

| designed to match with different size of extruder: | agent wanted |

| Production Capacity: | 50 pieces/month |

| Packing: | seaworthy packing |

| Delivery Date: | 30 days after receiving down payment |

Product Description

Automatic mesh belt screen changer

Performance characteristics:

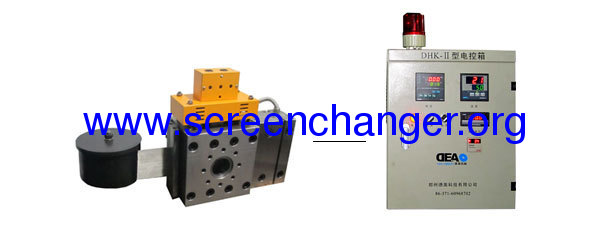

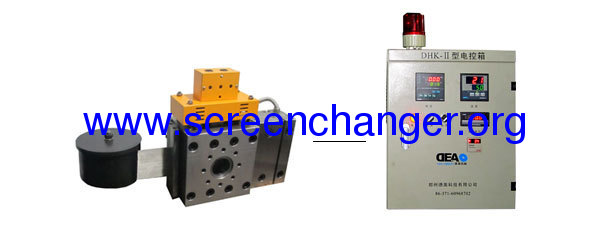

The automatic mesh belt screen changer is mainly composed of the screen changer, the heating and cooling system, and the electric control system. There is no need of manual operation of the screen changer because the material fluid inside flows by itself under the pressure caused by the melt production.

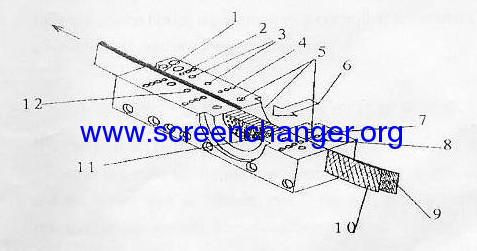

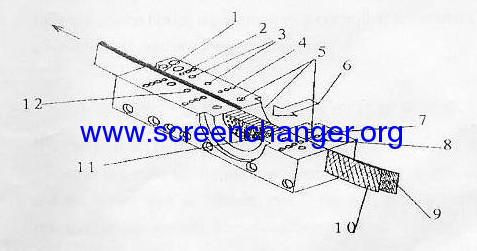

1)Moving screen mesh heater;

2)Adiabatic isolation hole

2)Adiabatic isolation hole

3)Export cooling area water holes

4)Adiabatic isolation hole

5)Filtering district heating holes

6)Flow direction

4)Adiabatic isolation hole

5)Filtering district heating holes

6)Flow direction

7)inlet heat insulation hole

8)outlet cooling water area

9)Fine mesh belt

10)Support mesh(coarse screen)

8)outlet cooling water area

9)Fine mesh belt

10)Support mesh(coarse screen)

11)Support of the porous plate mesh

12)outlet of cooling water holes

12)outlet of cooling water holes

Performance characteristics:

1\Automatical and continuous screen replacement without manual operation.

2\No fluctuation of material flow, no product deformation, excellent quality stability.

3\No waste product or waste material, and little material consumption occur when the screen changer works.

Application fields:

Mainly used for the production of PP, PE, ABS, PS, PMMA and other materials, and widely used for the cast film, sheet, plate, optical fiber, various drawings, granulators and other products of high quality and long production process .

Technical Data:

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |