single plate type double-working station screen changer

2500.0~9000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

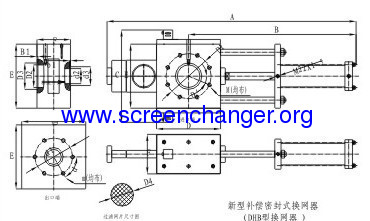

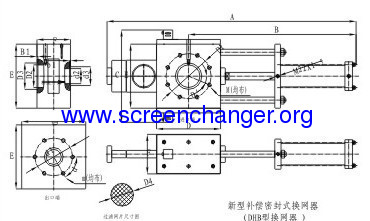

| Model No.: | DHB |

|---|---|

| Means of Transport: | Ocean, Air |

| Structure: | Hydraulic Filter |

| Function: | Screening Filter |

| Material: | Others |

| Brand Name: | Deao |

| screen changer for extrusion lines: | China made screen changer |

| Production Capacity: | 50 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | within 30 days after down payment received |

Product Description

Specifications

Extruder screen changer, screen changer, automatic tooling changer, tool changer, auto screen changer, double pillar screen changer

1. Extruder screen changer with single plates.

2. Automatic tooling screen changer has different diameters for changing nets.

3. Tool changer is equipped with different extruders.

4. Auto screen changer, double pillar hydraulic screen changer with double working position, single plate screen changer, single panel screen changer, single pillar screen changer, its diameter is from 70mm-300mm.

Technical Data

Type | Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Special installations

The DHB SERIES can be installed both horizontally and vertically and can be introduced into pre-existing installations or where the space available is restricted but without compromising high quality processing.

For maximum use of space, and economic advantage, several DHB series screen changers can be connected to one hydraulic unit.

Applications

Blown film and cast film (Bubble pack/ Medical/Food Wrap)

Sheet (Foam/Strapping/Plastic cardboard)

Coating (Hot melt adhesive)

Pipe ( Corrugated/Gas Pipe) and profile

Compounding (Master batch/filler)

Wire and cable extrusion

Tubing (Medical/Industrial/Irrigation)

Fibers ( Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers