The continuous backflush screen changer

1.0~40000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 50 pieces per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

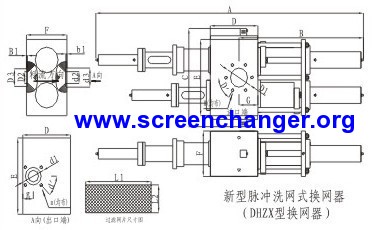

| Model No.: | DHZX |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Plastic Type: | PP/PE |

| Use: | Waste Plastic Crusher |

| Shaft Design: | Single |

| Brand Name: | Deao |

| Belong to: | parts and components |

| Function: | filter |

| Use for: | the production of plastic |

| Suitable materials: | almost all polymers |

| Service: | ODM/OEM |

| Production Capacity: | 50 pieces per month |

| Packing: | standerd wooden case |

| Delivery Date: | within 50 days after PO conformation |

Product Description

Specifications

The continuous backflush screen changer: screen washing online available, no production interrupt, suitable for high-end equipment production

The continuous backflush screen changer/pulse backflush screen changer for waste recyling machine

The continuous backflush screen changer is the latest product developed by Deao of self-owned Chinese invention patent and international invention patent. There is no need to change the screen, but backflush of rapid pulse by little clean material in the machine. It is a symbol of internationally advanced technology, and is especially applicable for the machines of waste recycling and granulating, and direct waste processing.

Performance Characteristics:

1,The continuous backflush screen changer is equipped with a strong pulse screen washing system (of self-owned patent ), screen washing online available, cleaning rate of the filtering screen up to 80%-95%, no production interrupt, more than 200 times of usage of the filtering screen (depending on the density of the screen).

2,Filtering area from 365 cm2to10000 cm2, initiative internationally (international patent), advanced technology, already put into practical application.

Benifits of the continuous backflush screen changer

Benifits of the continuous backflush screen changer

2, No need to change the screen, but backflush of rapid pulse by little clean material in the machine

3,Cleaning area of the filtering screen up to 80%-95%

4,No interrupt the product

5, The filtering screen can be used more than 100 times.(depending on the density of the screen)

PS:

It has been applied in the United States PS recycling machine. Its output is 1100kg/hr, filtration precision of 40-60 mesh, new screen pressure of 2.5Mpa, material pressure of 7.5Mpa after admixture. The material pressure reduced to 2.5 -2.7Mpa after strongly washing the filter, filter cleaning rate exceeds 90%.

.coating

.pipe

.compounding

.wire and cable

.tubing

.lab lines

.textiles (fiber and nonwovens)

.EVA. hot melt adhesive and PSA

.Pelletizing(strands and under water)

.Recycling of most polymers

.Blown film and cast film

.FPVC. Corrosive and degradable materials

Application cases of the continuous backflush screen changer

Application cases of the continuous backflush screen changer