Spare parts for screen changer

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | Screen changer DEAO MADE |

|---|---|

| Means of Transport: | Ocean |

| Structure: | Hydraulic Filter |

| Function: | Purification Filter |

| Material: | Others |

| Brand Name: | DEAO |

| SCREEN CHANGER FOR PELLETISERS: | CHINA MADE SCREEN CHANGER FOR POST FINISHING MACHINE |

| Production Capacity: | 20000 |

| Packing: | seaworthy |

| Delivery Date: | 1-days |

Product Description

- Long equipment life due to uncompromising quality of construction and materials

- Superior pellet quality through use of quality original parts

- Increased operator safety

- Maximum productivity through improved machine availability

- Long service life provides optimum return on your initial investment

- Guaranteed spare parts supply, long after original sale

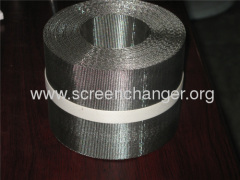

Single-plate, double-plate, single-column, double-column screen changer. Changing the screen hydraulically for easy production and maintenance.

Come with built-in sealing device to ensure sound tightness and allow for mass production of any polymers, capable of being coupled with extruders of various specifications.

Screen-changing time≤1 second. The filtering area may vary between Φ30mm-Φ250mm.

Come with grinding-resistant, pressure-resistant and high precision filter to ensure maximized filtering area and optimized filtering results.

Its performance will not be compromised when the pressure is kept between 25—30Mpa and temperature around 300°C.

Nearly all the polymers are fit for screen changer, such as PC, PMMA, PET, PVC, PS, PU, PP, PE, EVA, ABS, etc.