Pigment&masterbatch test small plastic injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SSF380-K5 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | SS |

| Power: | 380V,50HZ |

| injection weight: | 37g |

| clamp force: | 380kn |

| space between tie bars: | 240*240 |

| Min-max mould height: | 80~270 |

| Production Capacity: | 30 sets/month |

| Packing: | nylon plastic bag in container or plywood by LCL |

| Delivery Date: | 30 days |

Product Description

Test injection molding machine for masterbatches and pigments

The test small platic injection moulding machine is widely applied by world well known customers such as clariant,NHH, with good capacity, it's a good choice for masterbatch and pigment manufacturers.

You can send us for sample for free testing before you order the plastic injection machine, you can fully assure to buy this machine after your verifications.

You can send us the color plate's size, we can design the mold for you per your request and recommend the most suitable machine for you.

Main parameters of 38T plastic injection machine as below;

| Items | Parameter | Unit | Parameter Value |

| Injection Unit | Screw diameter | mm | 25 |

| Injection weight(PS) | g | 37 | |

| Oz | 1.31 | ||

| Clamping unit | Clamp force | KN | 380 |

| Open stroke | mm | 235 | |

| Distance between tie bars (W*H) | mm | 240*240 | |

| Max mould thickness | mm | 270 | |

| Min mould thickness | mm | 80 | |

| Ejector stroke | mm | 60 | |

| Ejector force | KN | 17.5 | |

| Ejector number | PC | 1 | |

| Dia of mould location hole | mm | 80 | |

| Others | Max pump pressure | Mpa | 14 |

| Pump motor power | KW | 4 | |

| Heating power | KW | 3.2 | |

| Machine dimension(L*W*H) | m | 2.9*1.0*1.4 | |

| Machine weight | T | 1.35 | |

| Oil tank capacity | L | 90 |

Double-cylinder balanced injection system;Standard features of color plate making injection molding machine;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mould adjust function;

Special designed screw for color chips making, of which can get good capacity of plasticizing.

Warranty; 1 Year

Spare parts;

1.Nozzle

2.Lubricate oil

3.Seal rings(5pcs)

4. Tool box

5. Other tools such as spanner, straight screwdrivers;

6. Crash pad

Color chips made by this small plastic injection machine;

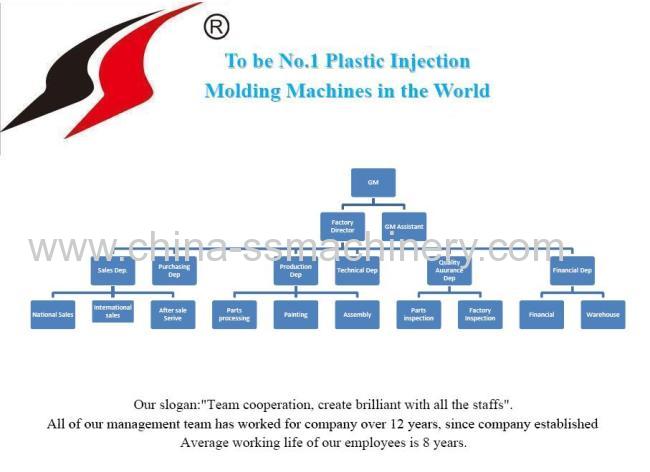

We shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

the average working life of the staffs is 8 years.