Hot sale injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SSF500-K5 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Shuangsheng |

| Power: | 50HZ |

| injection weight: | 64g |

| clamp force: | 500kn |

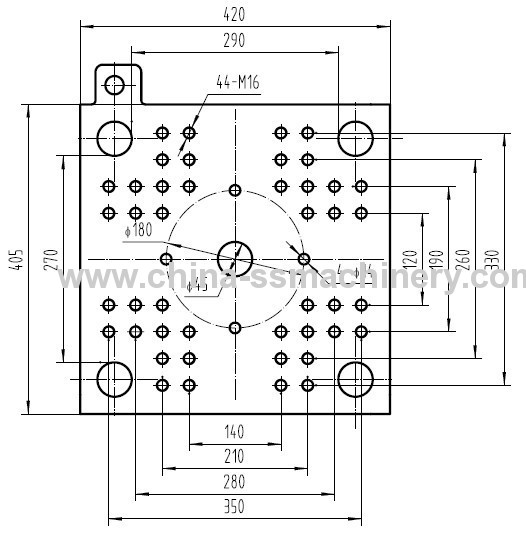

| space between tie bars: | 270*290 |

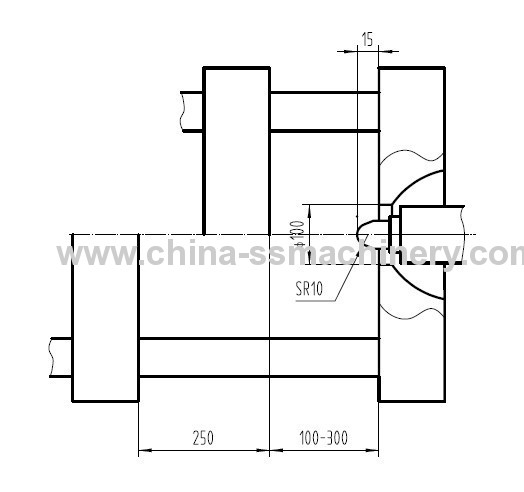

| Min-max mould height: | 100~300 |

| Color: | Green |

| Production Capacity: | 30sets/month |

| Packing: | nylon plastic bag in container or plywood |

| Delivery Date: | 30 days |

Product Description

Sell 50T injection molding machine

We are a small plastic injection molding machine manufacturer of which clamp force ranges from 25T to 168T.

Standard features;

1.Double-cylinder balanced injection system;

2.Multi-stage pressure &speed injection;

3.Back pressure adjustment device;

4.Low pressure mold protection;

5.Single hydraulic core pulling and inserting;

6.Multiple hydraulic ejector knock-out;

7.Mechanical, electrical safety device;

8.Auto lubrication system;

9.Hydraulic pressure full proportional control;

10.Computer control system;

11.Molding data memory system;

12.Automatic mould adjust function.

13.Energy saving with variable pump;

14.Bi-metallic screw to anti-corrosion, which is applicable to nylon or glass material.

15.Five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects;

16.Oil pipelines are positioned for aesthetic appearance and easy for maintenance;

17.The moving platen is fitted with adjustable slide support system to improve platen parallelism and provide better tie bar and mould protection and lengthen the working lifetime;

18.Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centering.

Optional auxiliary

Robot system

Hopper Magnet

Mold clamps

Water cooler

Plastic dehumidizer

Mold temperature controller

Oil temperature controller

Oil bypass filter

Spare parts;

1.Nozzle

2.Lubricate oil

3.Seal rings(5pcs)

4. Tool box

5. Other tools such as spanner, straight screwdrivers;

6. Crash pad

Mold platen drawing of 50T plastic injection molding machine;

Electricity connection box;

We make injection molding machines strictly follow ISO9001:2008 quality requirements, per customers's special requirements, CE also can be optional.

We shuangsheng plastic machinery respects staffs and values partnership of each customer, each cooperators, that why we can grow smoothly and steadily even the international ecomonic situation is not so optimistic.

The orgnization chart of our company, average working life of the staffs is 8 years.