70T horizontal plastic injection molding machine

1.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SSF700-K5 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Shuangsheng |

| Power: | 50HZ,380V |

| injection weight: | 103g |

| clamp force: | 700kn |

| space between tie bars(mm): | 315*300 |

| Min-max mould height(mm): | 130~320 |

| Machine Color: | Green |

| Oil tank capacity: | 130L |

| Machine weight: | 2.2T |

| Screw dia.: | 34mm |

| Screw L/D ratio: | 18.8 |

| Production Capacity: | 30sets/month |

| Packing: | nylon plastic bag in container |

| Delivery Date: | 30 days |

Product Description

The injection molding machine plates were designed using fenite element analysis software, ensuring a stable and rigid clamping system. Five-point inward moving toggle system ensure high rigidty and precision for mold clamping and also reducing stress and stain effects.

Plastic injection machine clamping unit is favored with robust casting construction with strengthened tie bar for maximum service life and best molding results.

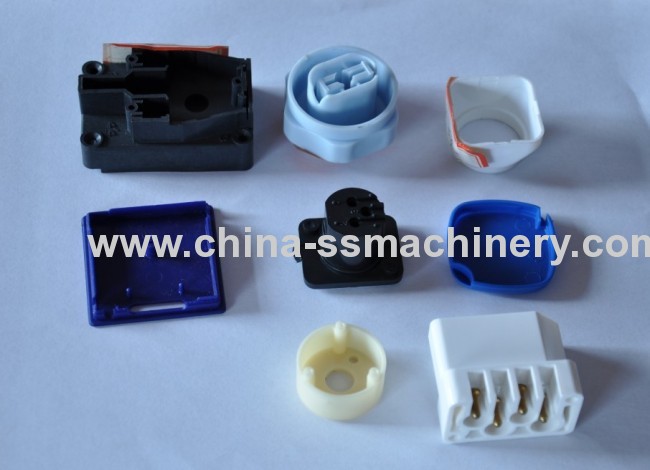

Plastic parts can be made by the injection moulding machine;

With continuous research and innovative, we have made great improvement on this model machine since 2002, you can fully rely on the machine stabability and capacity.